Premium reusable hydration bottle.

Premium reusable hydration bottle.

Premium reusable hydration bottle.

Premium reusable hydration bottle.

Premium reusable hydration bottle.

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Year: 2020

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Year: 2020

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Year: 2020

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Year: 2020

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Year: 2020

The objective of this project was to create a premium water bottle design that will be innovative and represent good value for money against established brands in the marketplace. The bottle was required to be aesthetically pleasing and have a high-quality feel to it.

My Role as a freelance Industrial Designer was to first explore materiality and understand the market and then provide a range of concepts suitable to the requirements and embrace the brands ‘design to delight’ ethos.

The objective of this project was to create a premium water bottle design that will be innovative and represent good value for money against established brands in the marketplace. The bottle was required to be aesthetically pleasing and have a high-quality feel to it.

My Role as a freelance Industrial Designer was to first explore materiality and understand the market and then provide a range of concepts suitable to the requirements and embrace the brands ‘design to delight’ ethos.

The objective of this project was to create a premium water bottle design that will be innovative and represent good value for money against established brands in the marketplace. The bottle was required to be aesthetically pleasing and have a high-quality feel to it.

My Role as a freelance Industrial Designer was to first explore materiality and understand the market and then provide a range of concepts suitable to the requirements and embrace the brands ‘design to delight’ ethos.

The objective of this project was to create a premium water bottle design that will be innovative and represent good value for money against established brands in the marketplace. The bottle was required to be aesthetically pleasing and have a high-quality feel to it.

My Role as a freelance Industrial Designer was to first explore materiality and understand the market and then provide a range of concepts suitable to the requirements and embrace the brands ‘design to delight’ ethos.

The objective of this project was to create a premium water bottle design that will be innovative and represent good value for money against established brands in the marketplace. The bottle was required to be aesthetically pleasing and have a high-quality feel to it.

My Role as a freelance Industrial Designer was to first explore materiality and understand the market and then provide a range of concepts suitable to the requirements and embrace the brands ‘design to delight’ ethos.

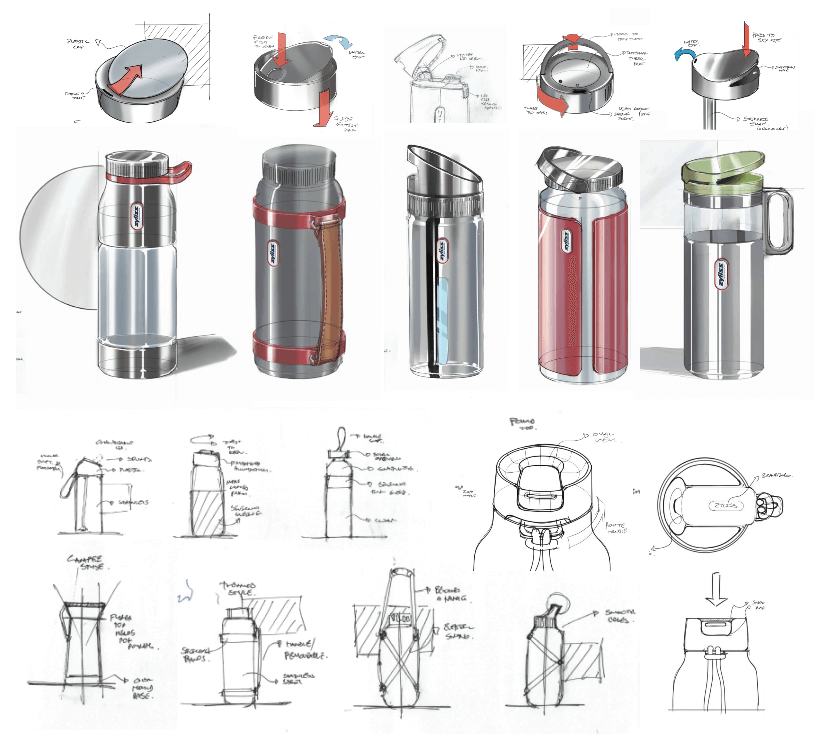

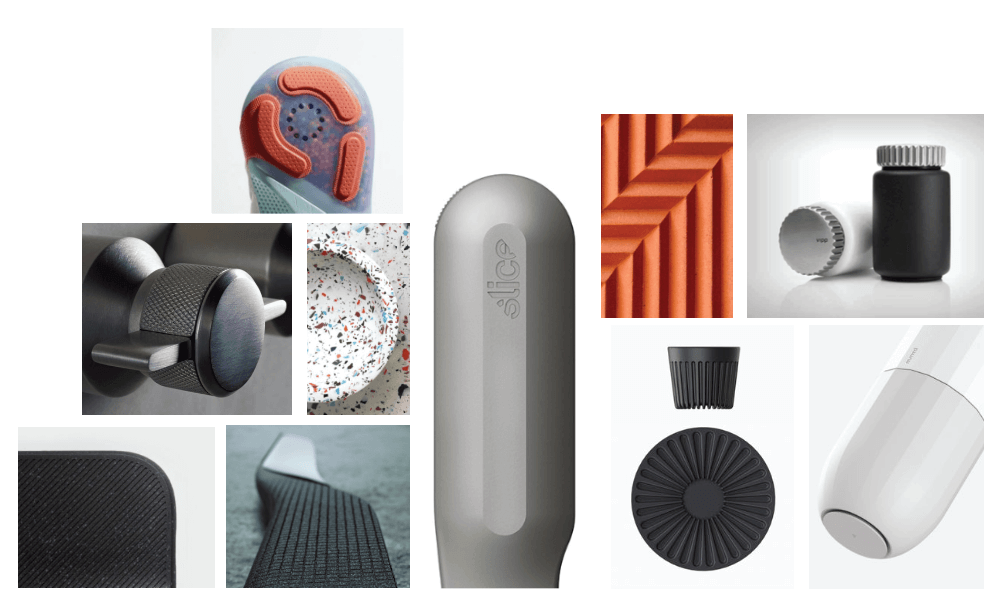

Early ideation

The ideation process started with a mood board and looking at existing shapes in the market and how to differentiate the product with new and innovative looks.

Each design looked at form language and different options for a user-operated sealing lid.

Early ideation

The ideation process started with a mood board and looking at existing shapes in the market and how to differentiate the product with new and innovative looks.

Each design looked at form language and different options for a user-operated sealing lid.

Early ideation

The ideation process started with a mood board and looking at existing shapes in the market and how to differentiate the product with new and innovative looks.

Each design looked at form language and different options for a user-operated sealing lid.

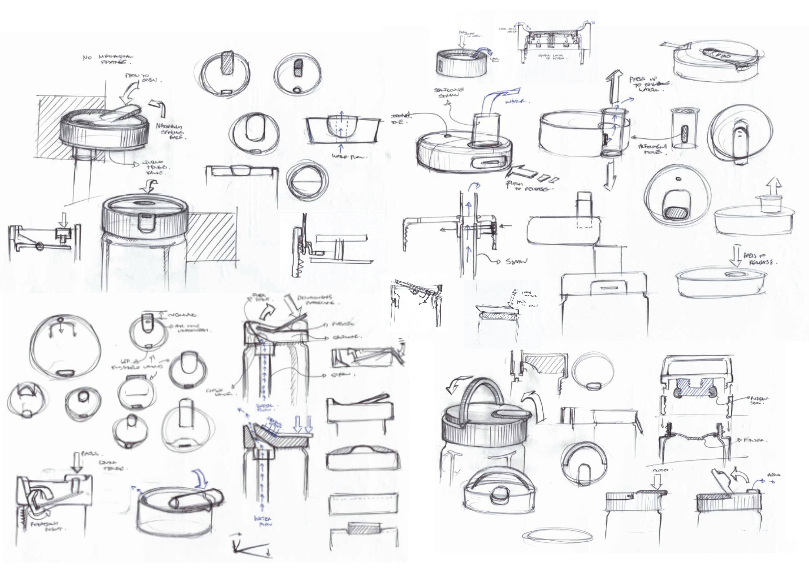

Early ideation

The ideation process started with a mood board and looking at existing shapes in the market and how to differentiate the product with new and innovative looks.

Each design looked at form language and different options for a user-operated sealing lid.

Early ideation

The ideation process started with a mood board and looking at existing shapes in the market and how to differentiate the product with new and innovative looks.

Each design looked at form language and different options for a user-operated sealing lid.

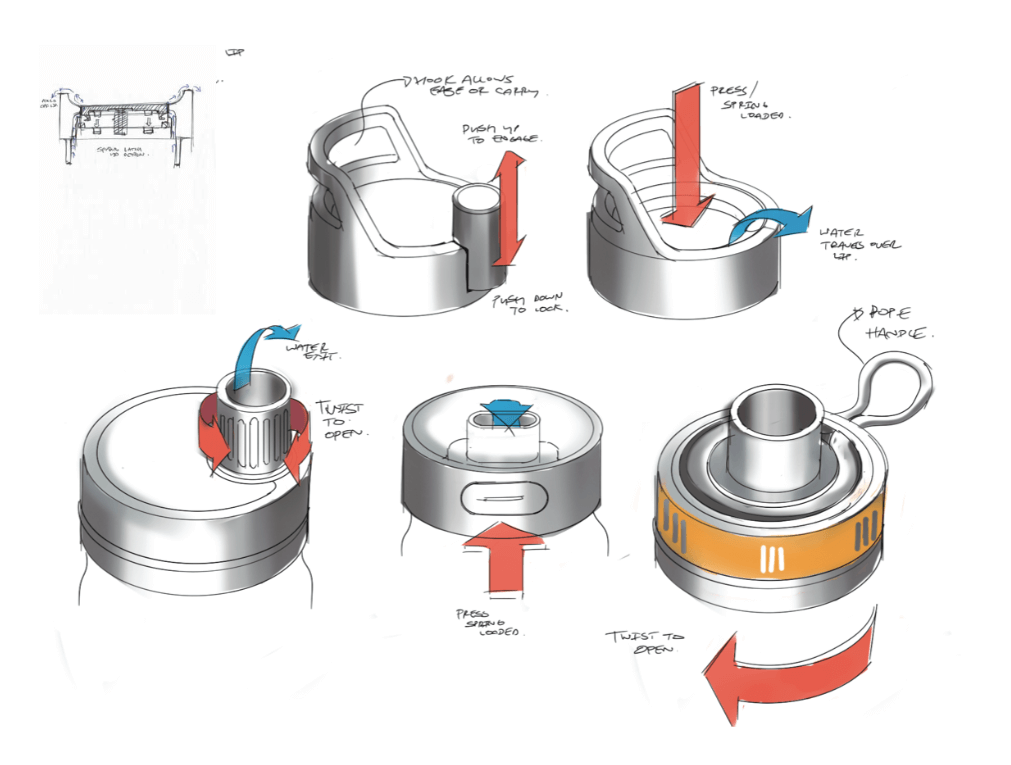

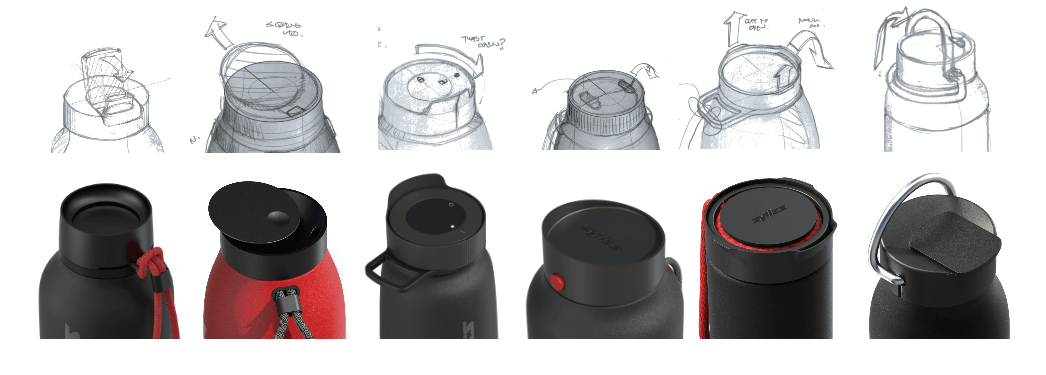

Mechanical ideation

Quick hand sketches allowed me to ideate mechanical lid designs and investigate feasible production methods at an early stage in the project.

Mechanical ideation

Quick hand sketches allowed me to ideate mechanical lid designs and investigate feasible production methods at an early stage in the project.

Mechanical ideation

Quick hand sketches allowed me to ideate mechanical lid designs and investigate feasible production methods at an early stage in the project.

Mechanical ideation

Quick hand sketches allowed me to ideate mechanical lid designs and investigate feasible production methods at an early stage in the project.

Mechanical ideation

Quick hand sketches allowed me to ideate mechanical lid designs and investigate feasible production methods at an early stage in the project.

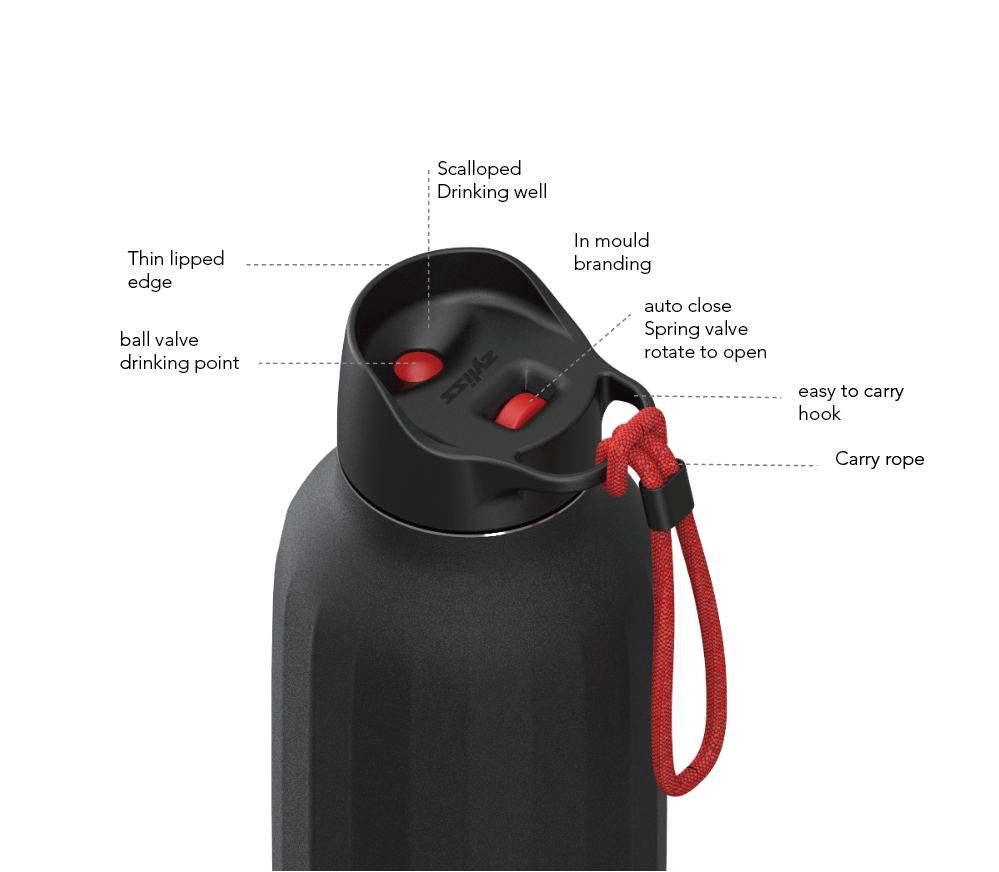

Concepts.

Based on the existing ideation and ongoing communication six initial concepts were presented to the client for review.

A mood board was created to help convey CMF direction for the project and the concepts were efficiently 3d modeled and rendered to help convey materiality and textures.

Each concept provided an innovative lid solution leaving the options open to further mechanical development.

Concepts.

Based on the existing ideation and ongoing communication six initial concepts were presented to the client for review.

A mood board was created to help convey CMF direction for the project and the concepts were efficiently 3d modeled and rendered to help convey materiality and textures.

Each concept provided an innovative lid solution leaving the options open to further mechanical development.

Concepts.

Based on the existing ideation and ongoing communication six initial concepts were presented to the client for review.

A mood board was created to help convey CMF direction for the project and the concepts were efficiently 3d modeled and rendered to help convey materiality and textures.

Each concept provided an innovative lid solution leaving the options open to further mechanical development.

Concepts.

Based on the existing ideation and ongoing communication six initial concepts were presented to the client for review.

A mood board was created to help convey CMF direction for the project and the concepts were efficiently 3d modeled and rendered to help convey materiality and textures.

Each concept provided an innovative lid solution leaving the options open to further mechanical development.

Concepts.

Based on the existing ideation and ongoing communication six initial concepts were presented to the client for review.

A mood board was created to help convey CMF direction for the project and the concepts were efficiently 3d modeled and rendered to help convey materiality and textures.

Each concept provided an innovative lid solution leaving the options open to further mechanical development.

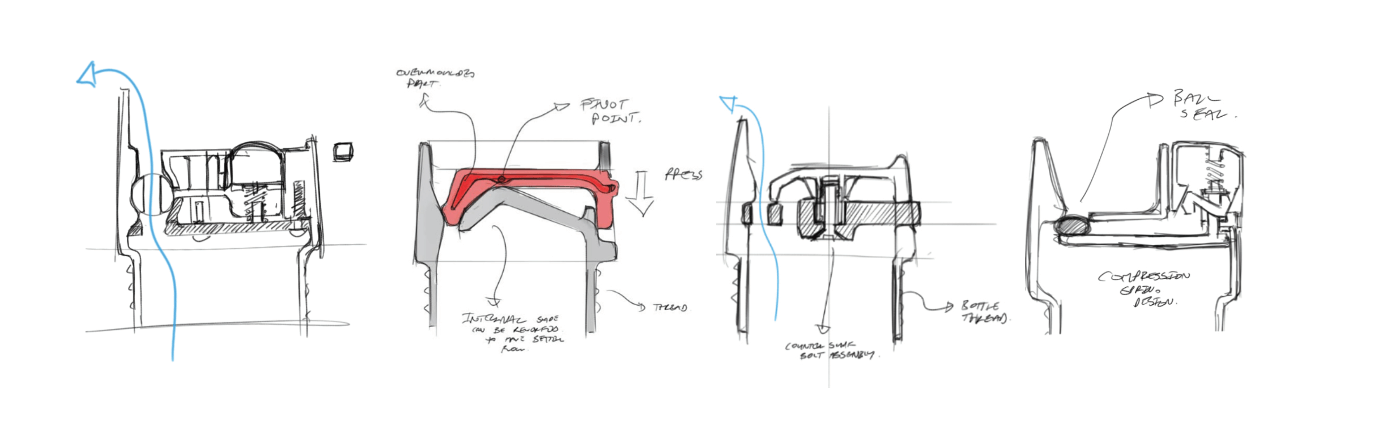

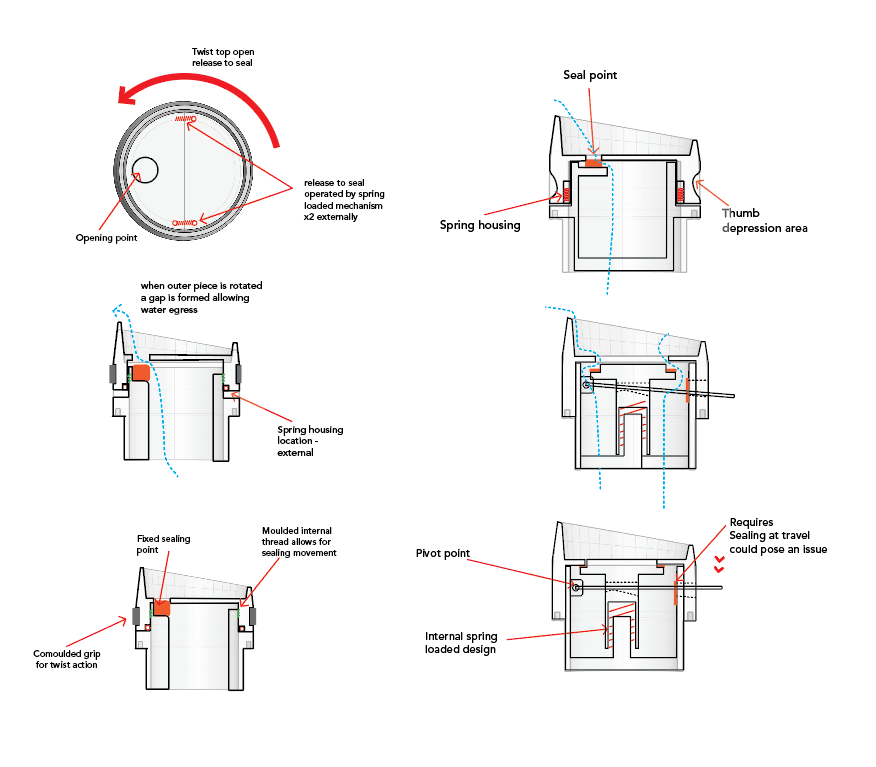

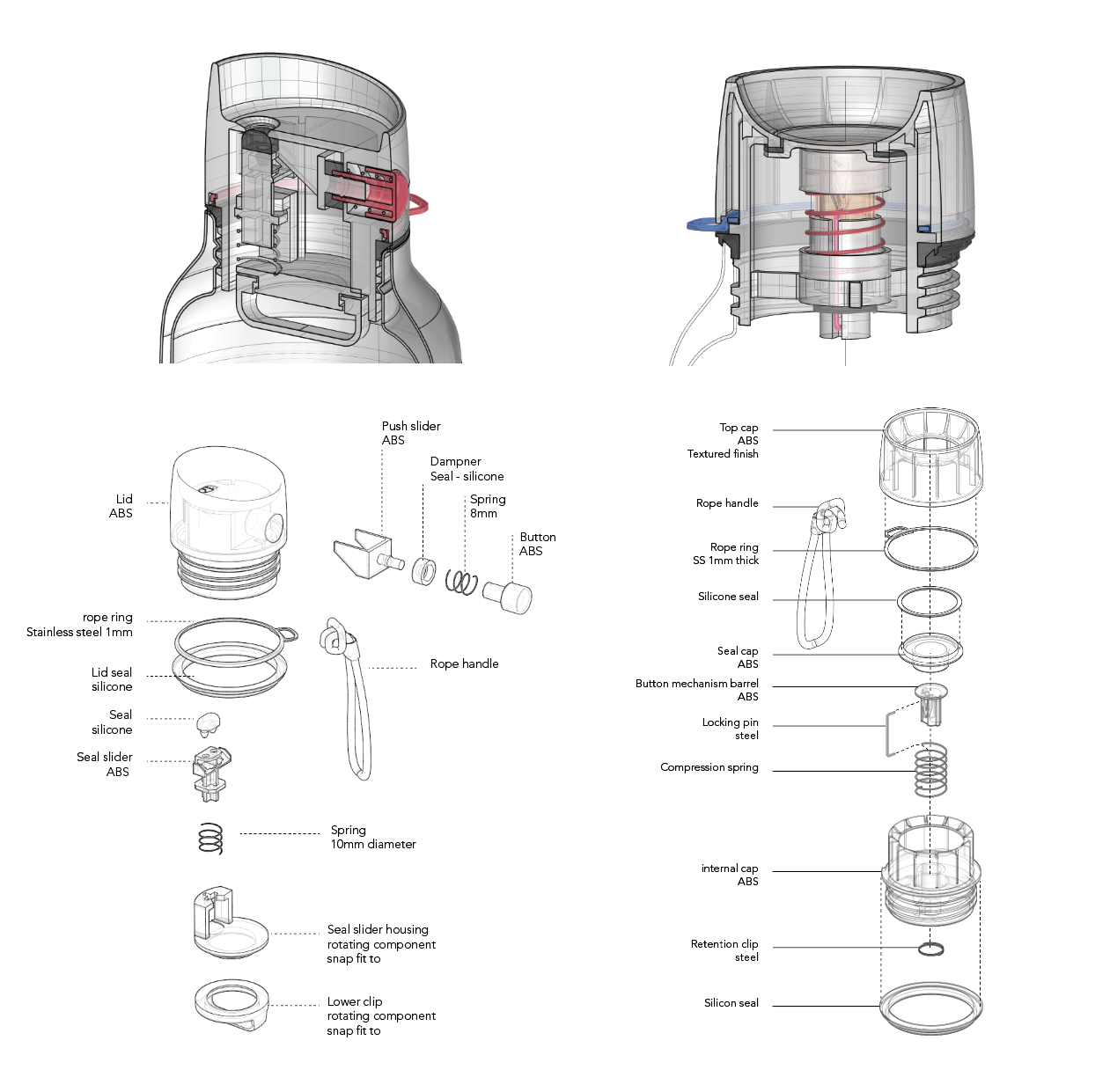

Understanding.

By Using 2D drawings I was able further understand the components required to create the mechanical assembly of the sealing lid designs.

IP review.

During this process I also conducted an IP review to ensure the designs were not already utilised in another product on the market.

Understanding.

By Using 2D drawings I was able further understand the components required to create the mechanical assembly of the sealing lid designs.

IP review.

During this process I also conducted an IP review to ensure the designs were not already utilised in another product on the market.

Understanding.

By Using 2D drawings I was able further understand the components required to create the mechanical assembly of the sealing lid designs.

IP review.

During this process I also conducted an IP review to ensure the designs were not already utilised in another product on the market.

Understanding.

By Using 2D drawings I was able further understand the components required to create the mechanical assembly of the sealing lid designs.

IP review.

During this process I also conducted an IP review to ensure the designs were not already utilised in another product on the market.

Understanding.

By Using 2D drawings I was able further understand the components required to create the mechanical assembly of the sealing lid designs.

IP review.

During this process I also conducted an IP review to ensure the designs were not already utilised in another product on the market.

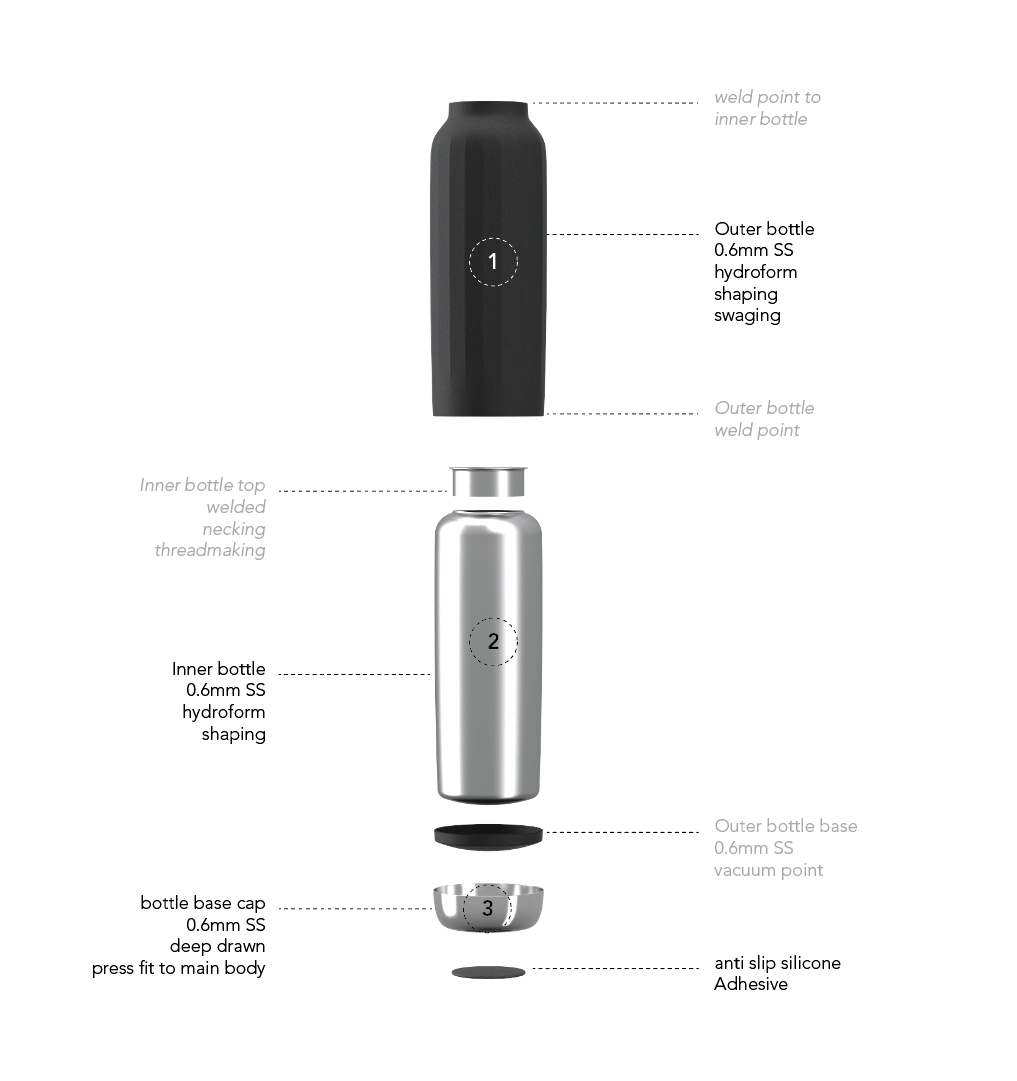

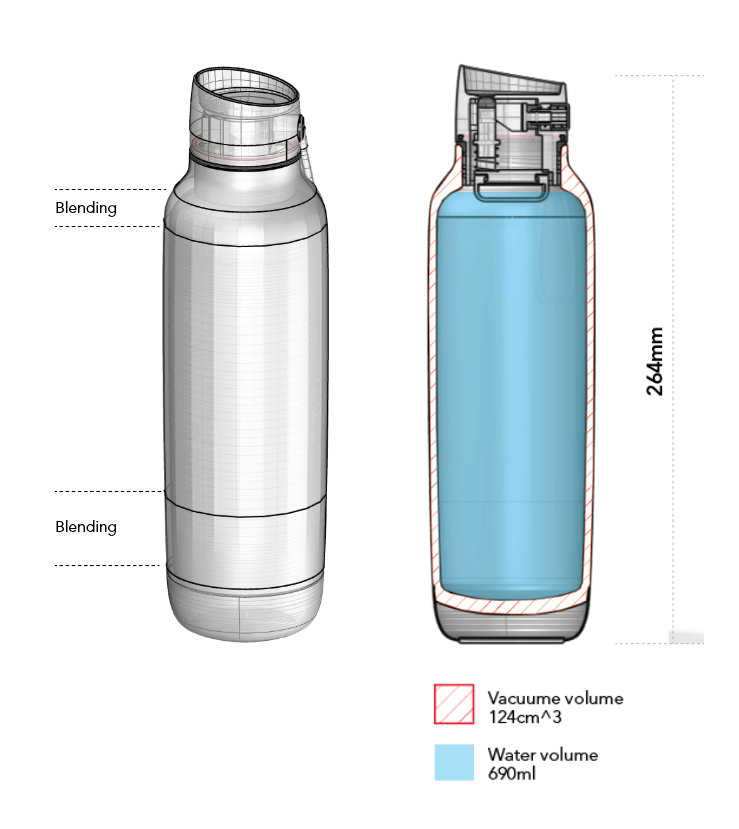

Design for manufacture

The 3D model allowed me to calculate the internal volumes and check formability of the bottle. This helped me understand the tooling and assembly processes required to achieve the shape.

Design for manufacture

The 3D model allowed me to calculate the internal volumes and check formability of the bottle. This helped me understand the tooling and assembly processes required to achieve the shape.

Lid mechanism.

Two 3D mockups where produced of the mechanical components to communicate the idea to the client. Each mockup had a sealing component and moving parts in the assembly.

Lid mechanism.

Two 3D mockups where produced of the mechanical components to communicate the idea to the client. Each mockup had a sealing component and moving parts in the assembly.

Lid mechanism.

Two 3D mockups where produced of the mechanical components to communicate the idea to the client. Each mockup had a sealing component and moving parts in the assembly.

Lid mechanism.

Two 3D mockups where produced of the mechanical components to communicate the idea to the client. Each mockup had a sealing component and moving parts in the assembly.

Other projects.

Trailtech Battery12v Trail camera Battery

Cast Iron LidsIronclad Enamelware Lids

RECONTrolling motor

The Oracle JetEspresso Machine

Air D1Luxury Loudspeaker

Retail CartPortable Retail Display Cart

Lowrance Eagle seriesFish Finder/chart plotter

Dock E30Studio Quality Compact Speaker

Resn labsSemi-permanent installation in Shenzhen China

HikoterraH4 Power System Visuals

NSX - UltrawideUltrawide marine display.

Jones JrMinimal multi-purpose task lamp

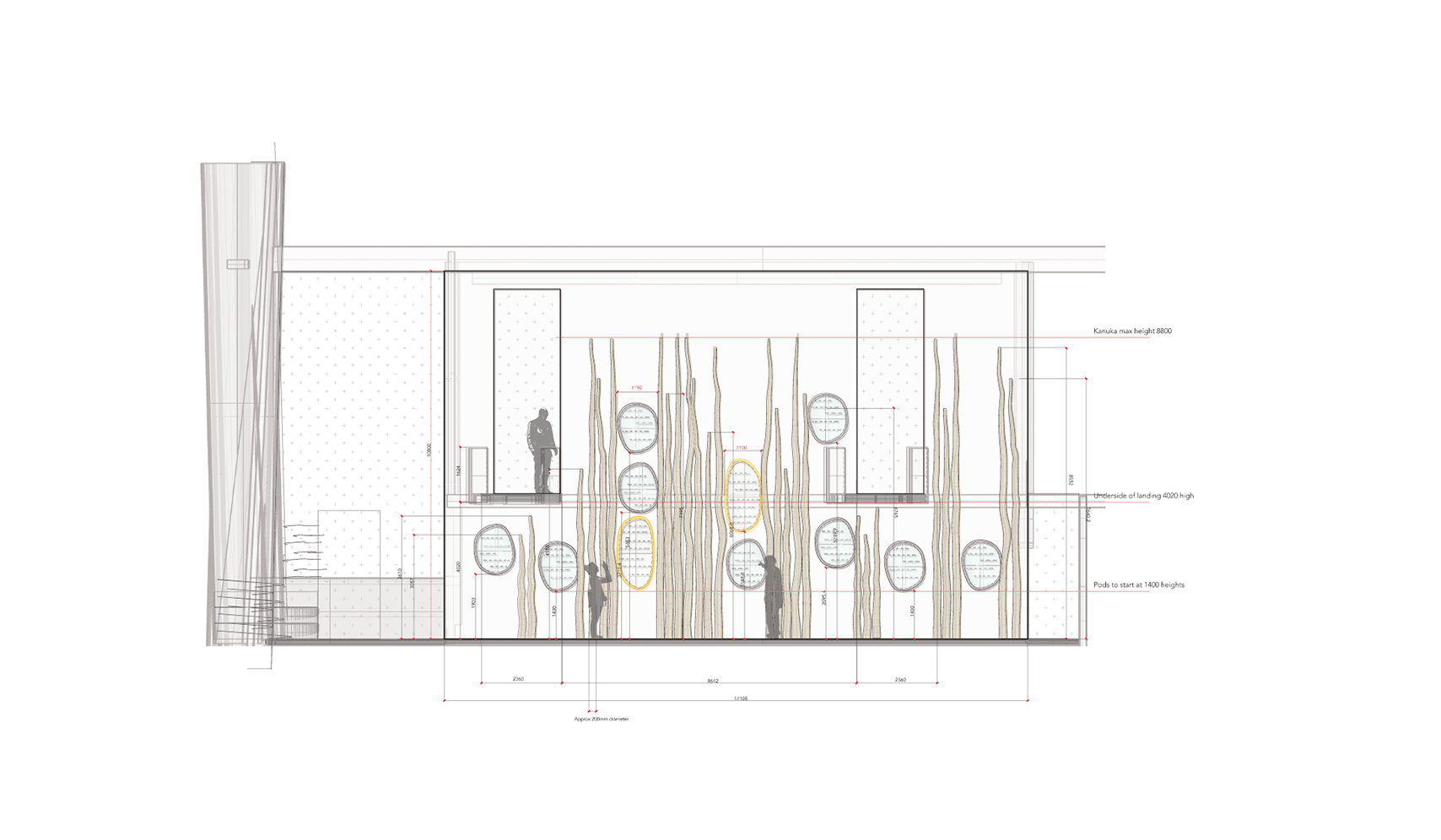

Ko Te Kihikihi Taku IngoaGovett Brewster Art Gallery

Ironclad BambooBamboo lids and Packaging

OrbitremoteA new frontier in remote audio control

Rotoiti BathMinimal aesthetic, compound curvature bathtub

BrevilleA selection of projects

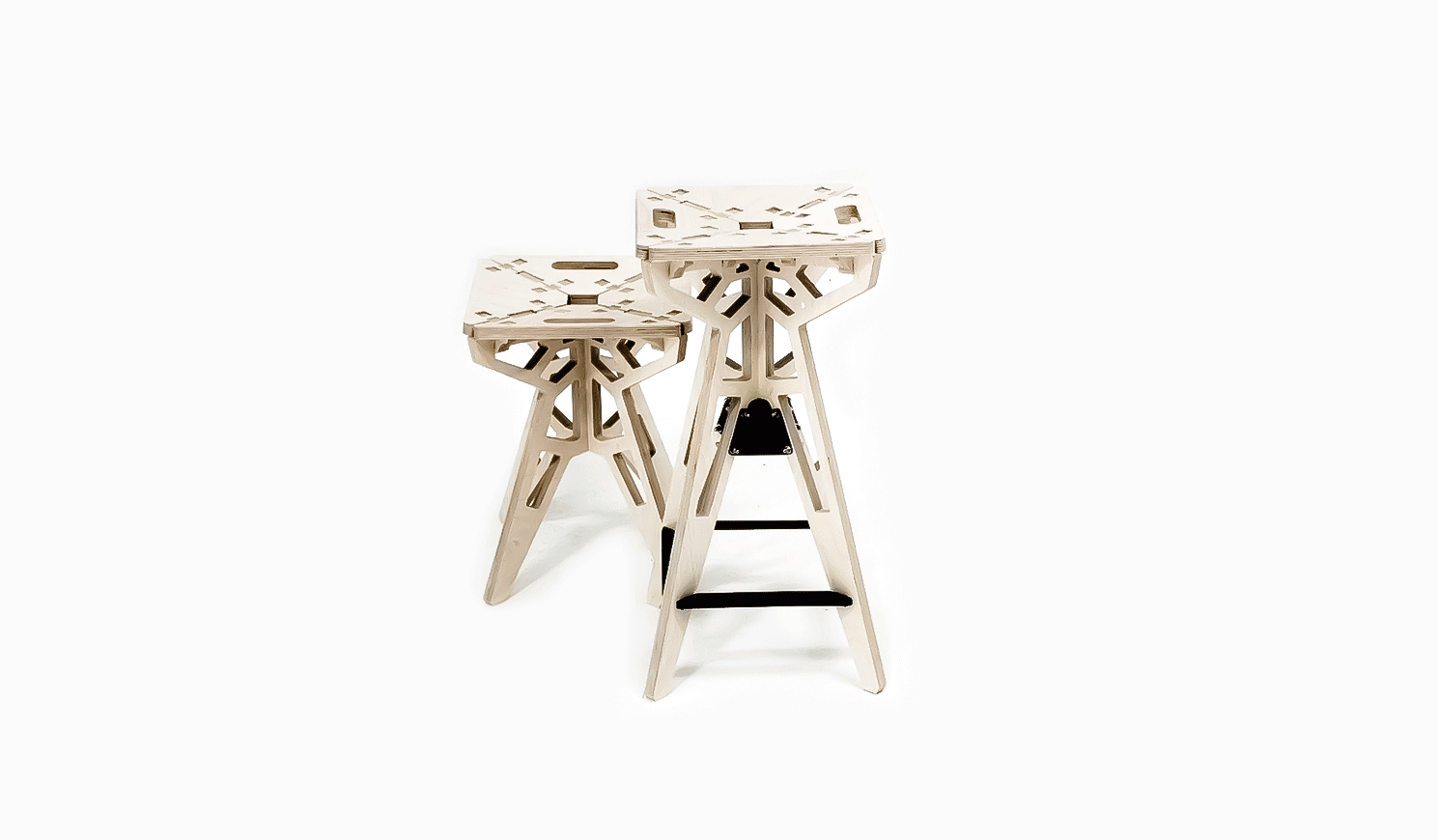

Space stoolsCNC cut stools

TVTRCompact soundbar

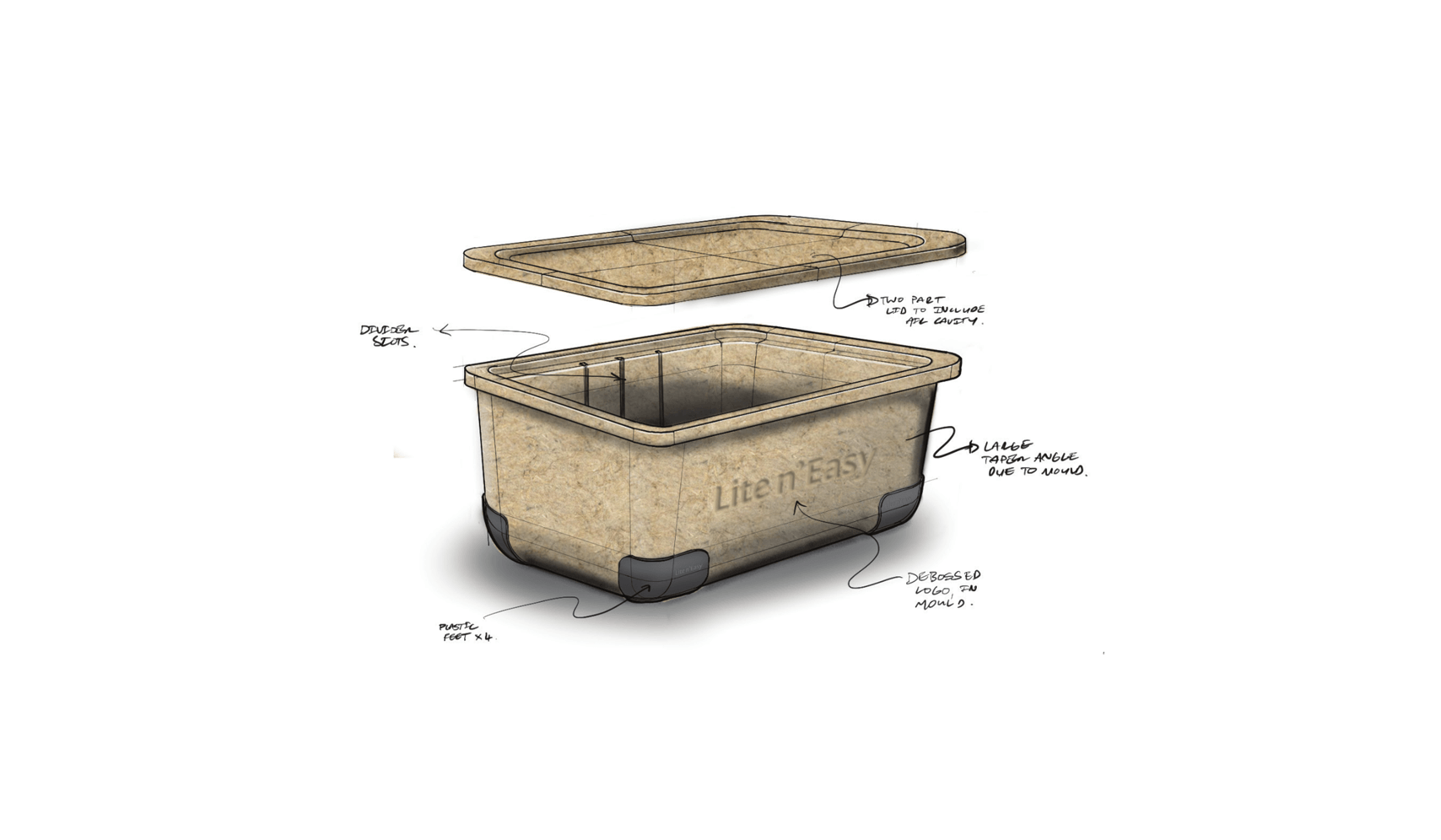

ThermoguardSustainable and re-useable food box

CEO SuiteChildrens desk and chair

Te MoungaCultural history exhibit

Gallipoli: The Scale of our WarExhibition furniture build

P70wAll in one soundbar

Meet the localsWellington zoo design and build

PK-01Portable kitchen

Maples kennelFlat pack dog kennel

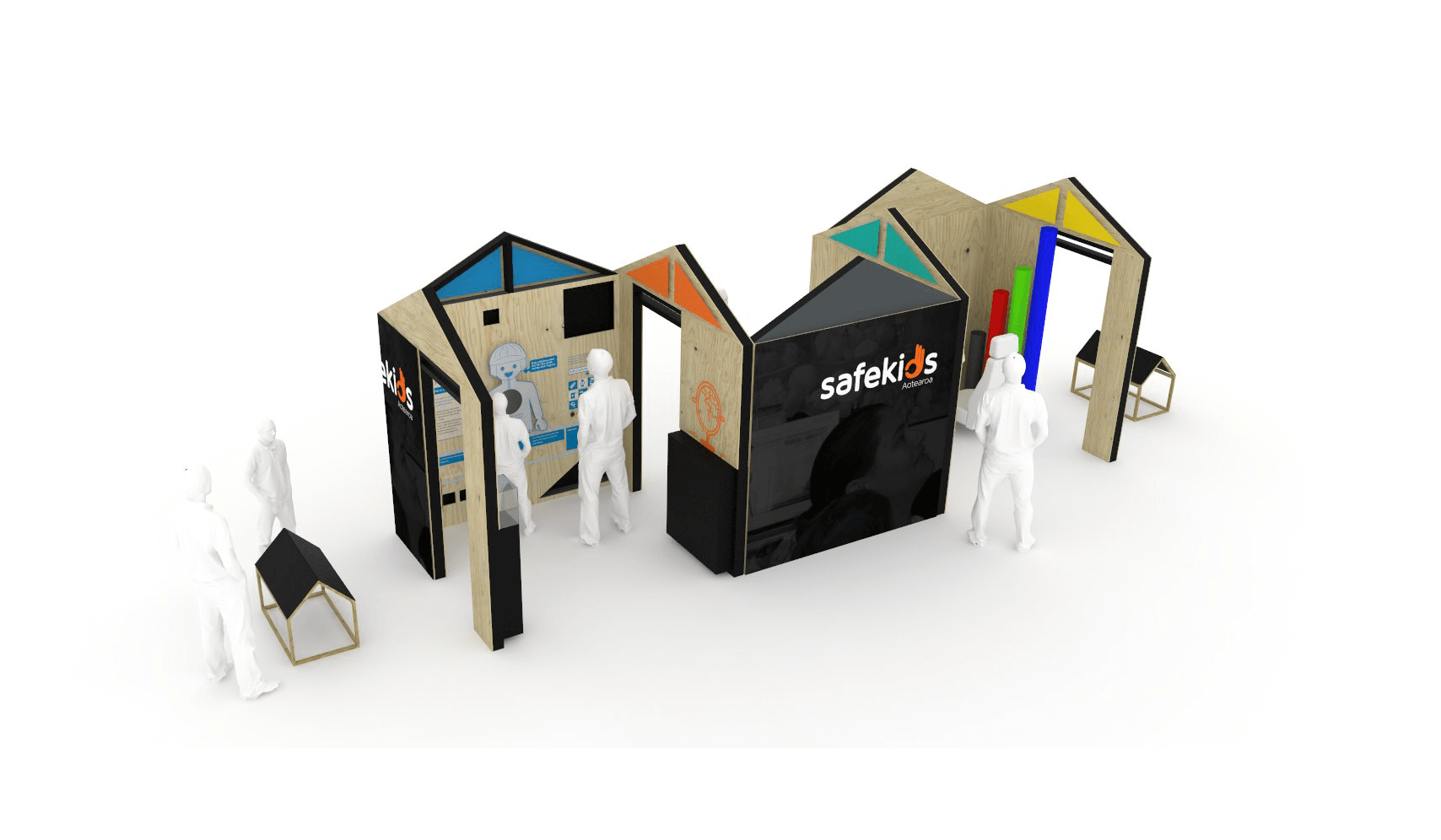

SafeKids AotearoaTouring popup exhibition

Barnaby Ward Design

5x Central Road, Kingsland

Auckland, 1021, NZ

© 2026

Book a Call

Book a Call Instagram.

Instagram. linkedin.

linkedin.