A compact TV Loundspeaker.

A compact TV Loundspeaker.

A compact TV Loundspeaker.

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Client: Orbitsound

Year: 2021

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Client: Orbitsound

Year: 2021

Project: Freelance

Disciplines:

Industrial Design

Mechanical Design

Client: Orbitsound

Year: 2021

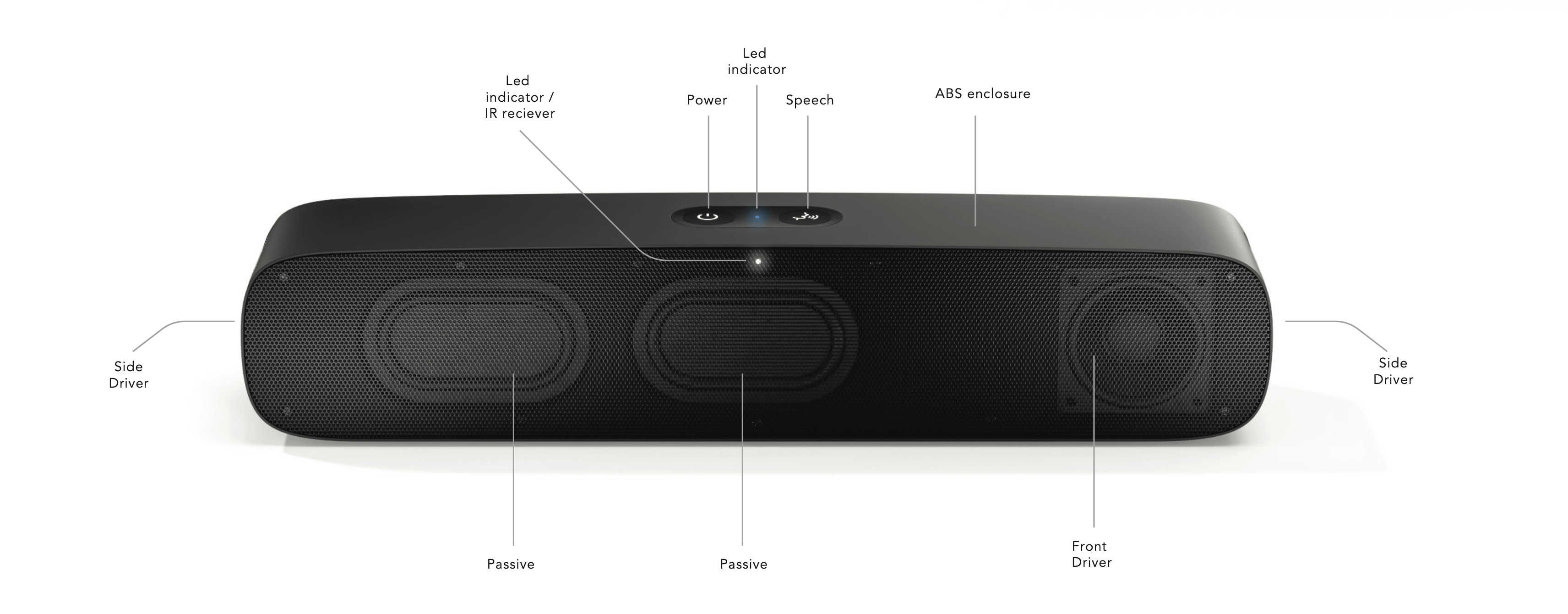

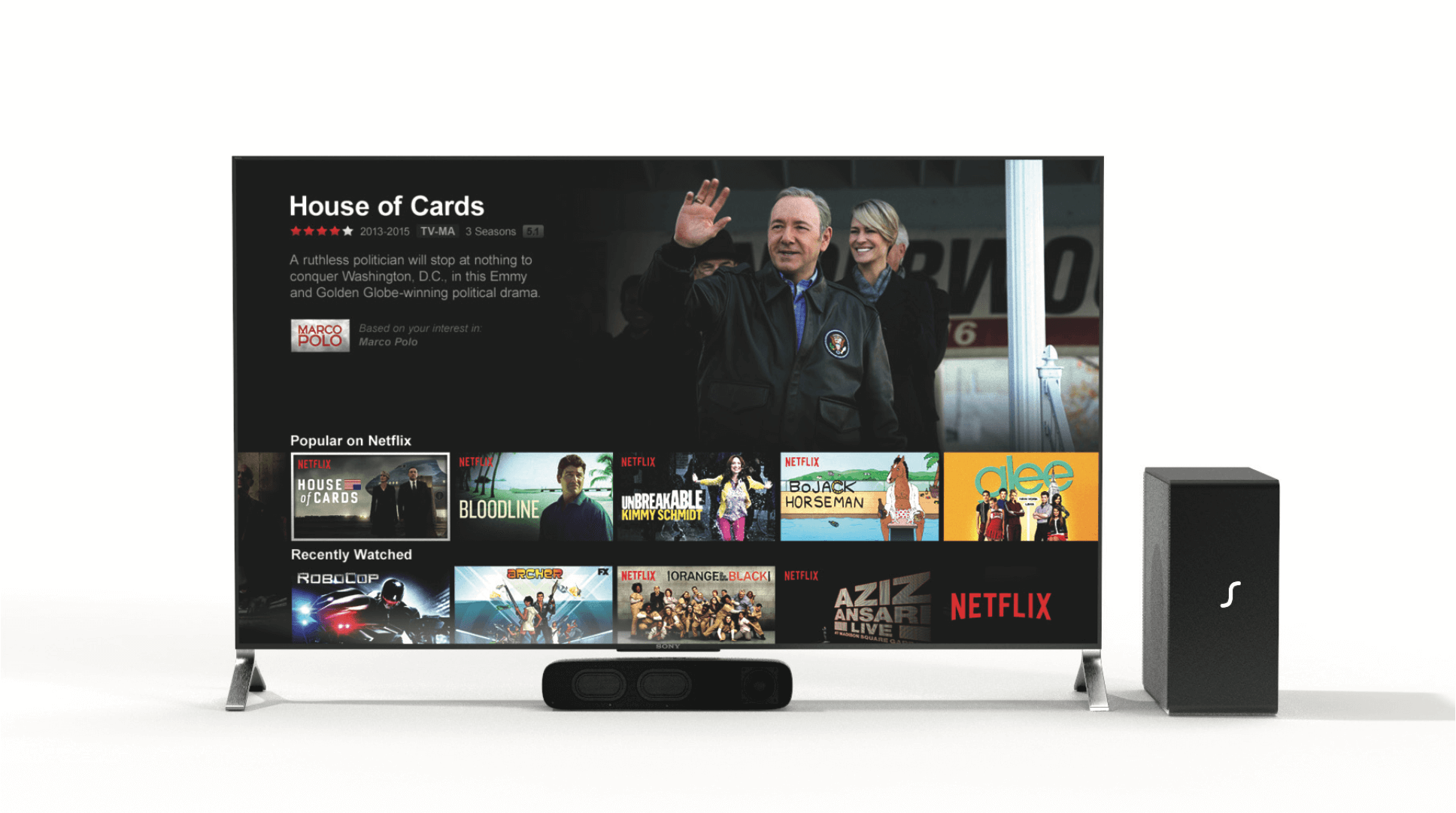

Working as a freelancer I was asked to design a compact soundbar utilizing Orbitsounds patented technology Airsound. The TVTR is a new product designed to recognize the changing needs of the home, the improvements in TV quality pictures and sound and the vastly varied programs available.

Working as a freelancer I was asked to design a compact soundbar utilizing Orbitsounds patented technology Airsound. The TVTR is a new product designed to recognize the changing needs of the home, the improvements in TV quality pictures and sound and the vastly varied programs available.

Working as a freelancer I was asked to design a compact soundbar utilizing Orbitsounds patented technology Airsound. The TVTR is a new product designed to recognize the changing needs of the home, the improvements in TV quality pictures and sound and the vastly varied programs available.

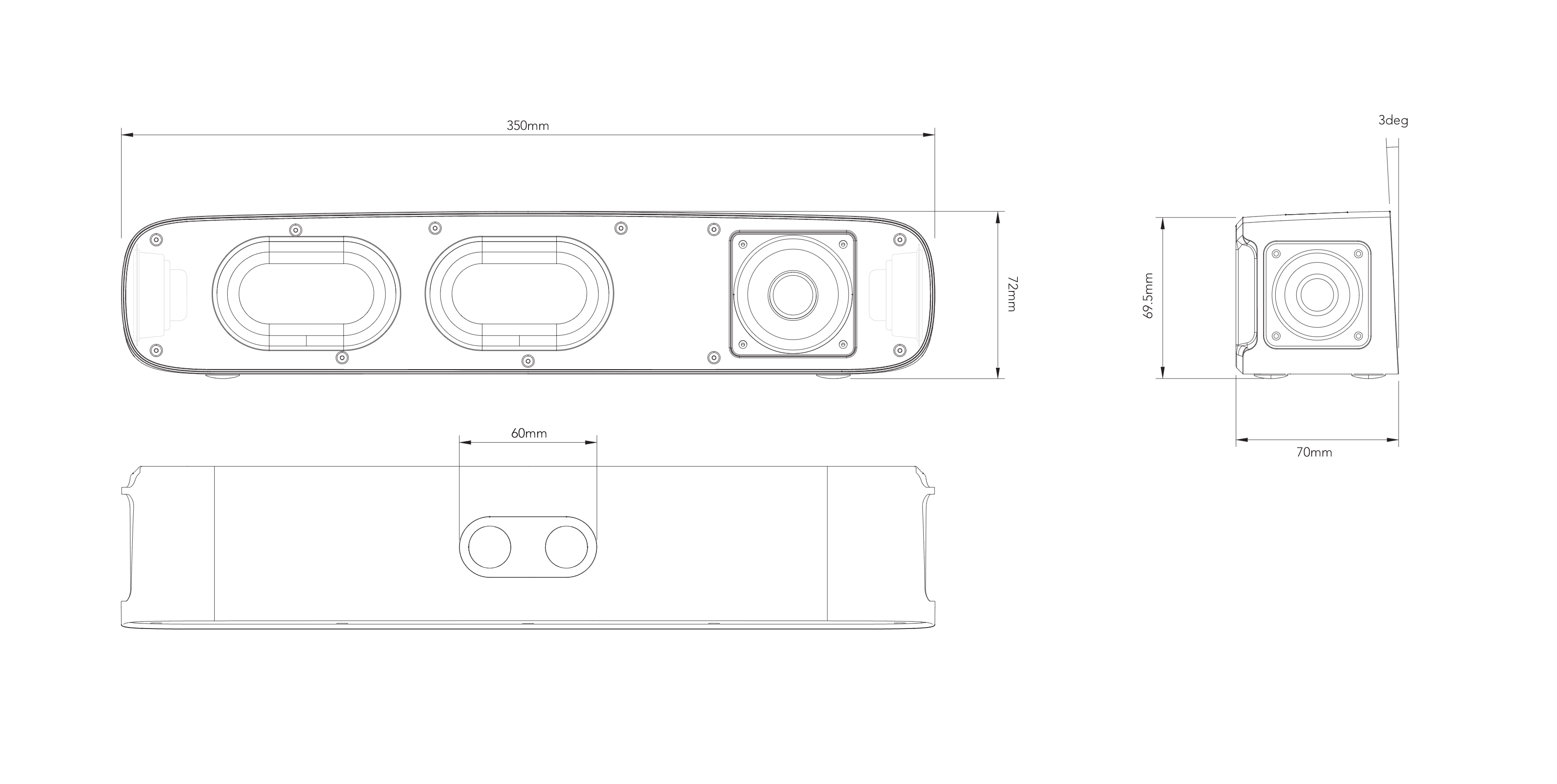

The product design had to be within the dimensional parameters demanded by the physics of sound reproduction as well as to be acceptable in the consumer's home. The visual appearance and design is smart but not obtrusive and accepts a small range of colorways. The ‘sub’ is an existing Orbitsound design and is a passive unit with a wired connection from the bar.

Design for manufacture

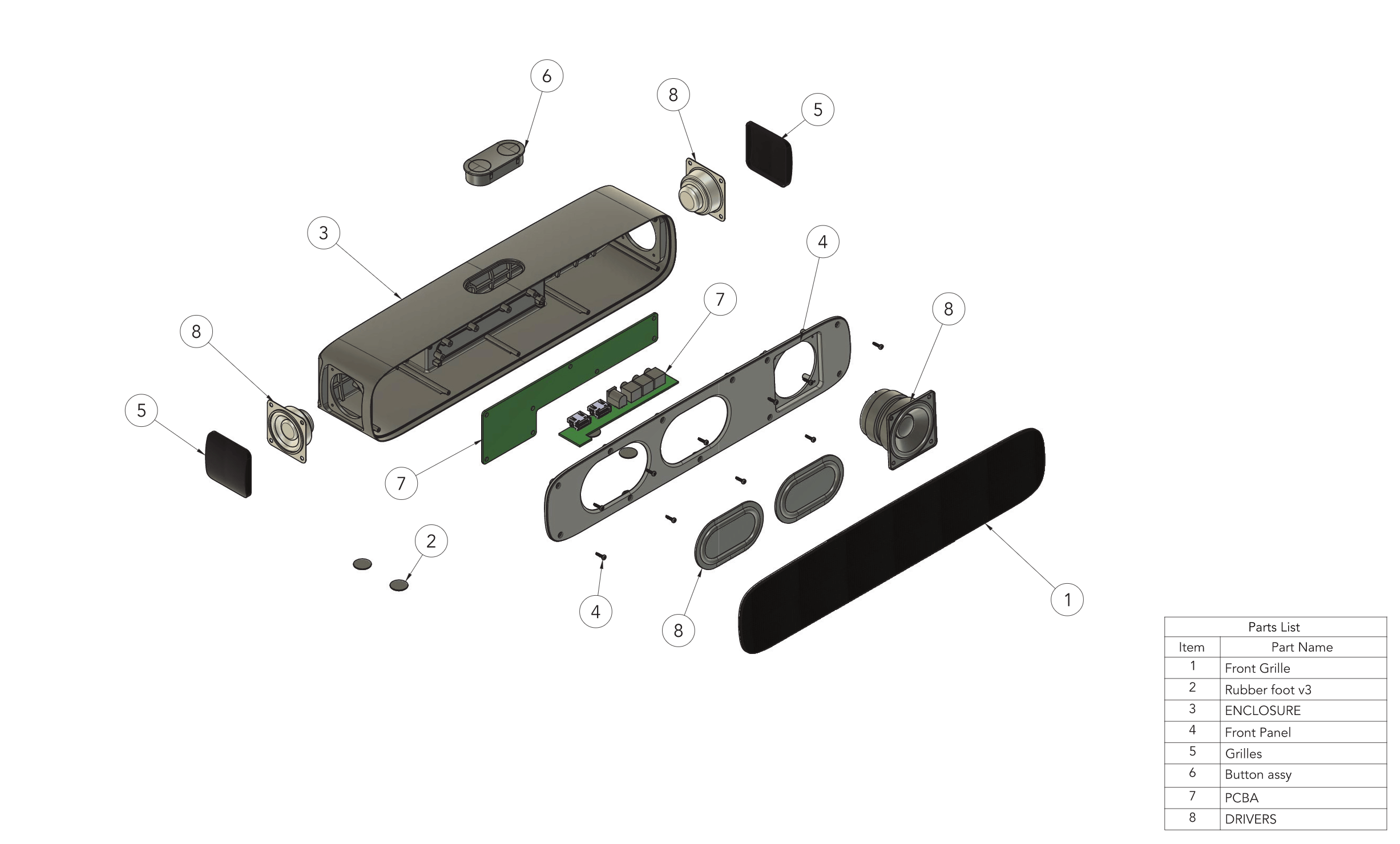

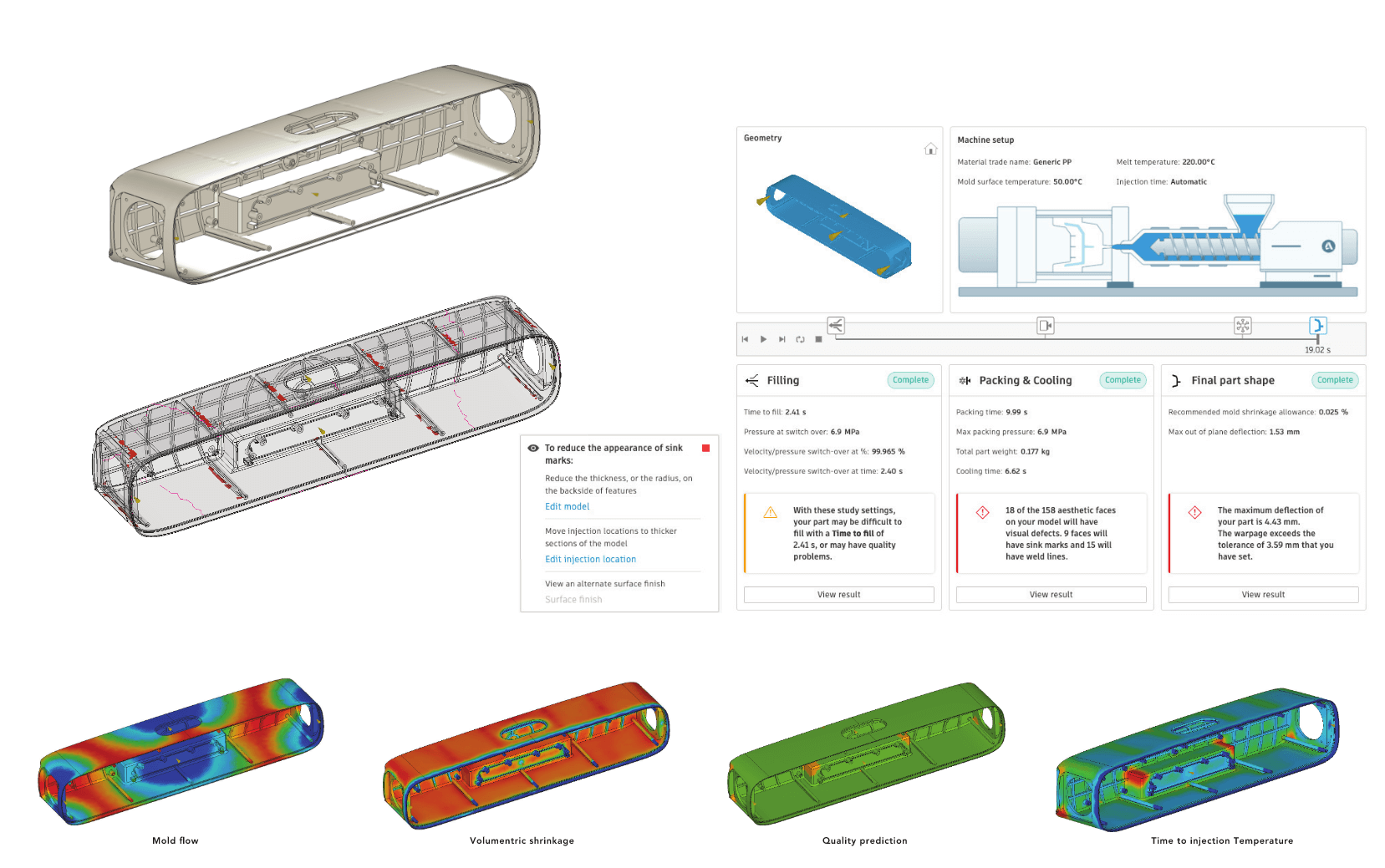

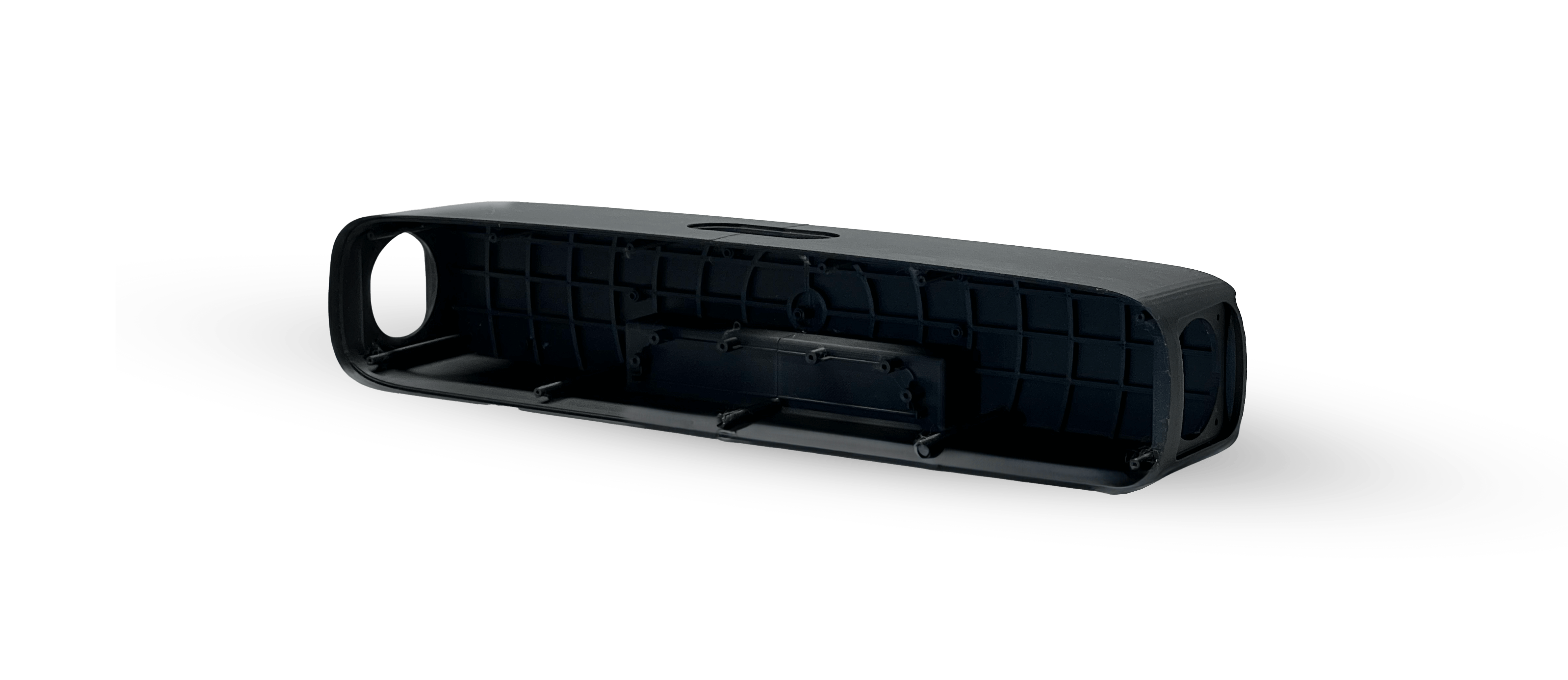

The brief was to produce a product that satisfies the crowded market but meets a low cost criteria. I produced working drawings for a prototype that would be handed off to the supplier including initial injection molding studies so that the plastic parts were 'tool ready'.

The aim was to allow the client to understand the total BOM cost, A 3D-printed enclosure was created for testing.

Design for manufacture

The brief was to produce a product that satisfies the crowded market but meets a low cost criteria. I produced working drawings for a prototype that would be handed off to the supplier including initial injection molding studies so that the plastic parts were 'tool ready'.

The aim was to allow the client to understand the total BOM cost, A 3D-printed enclosure was created for testing.

Design for manufacture

The brief was to produce a product that satisfies the crowded market but meets a low cost criteria. I produced working drawings for a prototype that would be handed off to the supplier including initial injection molding studies so that the plastic parts were 'tool ready'.

The aim was to allow the client to understand the total BOM cost, A 3D-printed enclosure was created for testing.

Design for manufacture

The brief was to produce a product that satisfies the crowded market but meets a low cost criteria. I produced working drawings for a prototype that would be handed off to the supplier including initial injection molding studies so that the plastic parts were 'tool ready'.

The aim was to allow the client to understand the total BOM cost, A 3D-printed enclosure was created for testing.

Design for manufacture

The brief was to produce a product that satisfies the crowded market but meets a low cost criteria. I produced working drawings for a prototype that would be handed off to the supplier including initial injection molding studies so that the plastic parts were 'tool ready'.

The aim was to allow the client to understand the total BOM cost, A 3D-printed enclosure was created for testing.

Other projects.

Trailtech Battery12v Trail camera Battery

Cast Iron LidsIronclad Enamelware Lids

RECONTrolling motor

The Oracle JetEspresso Machine

Air D1Luxury Loudspeaker

Hydration BottlePremium Reuseable Water Bottle

Retail CartPortable Retail Display Cart

Lowrance Eagle seriesFish Finder/chart plotter

Dock E30Studio Quality Compact Speaker

Resn labsSemi-permanent installation in Shenzhen China

HikoterraH4 Power System Visuals

NSX - UltrawideUltrawide marine display.

Jones JrMinimal multi-purpose task lamp

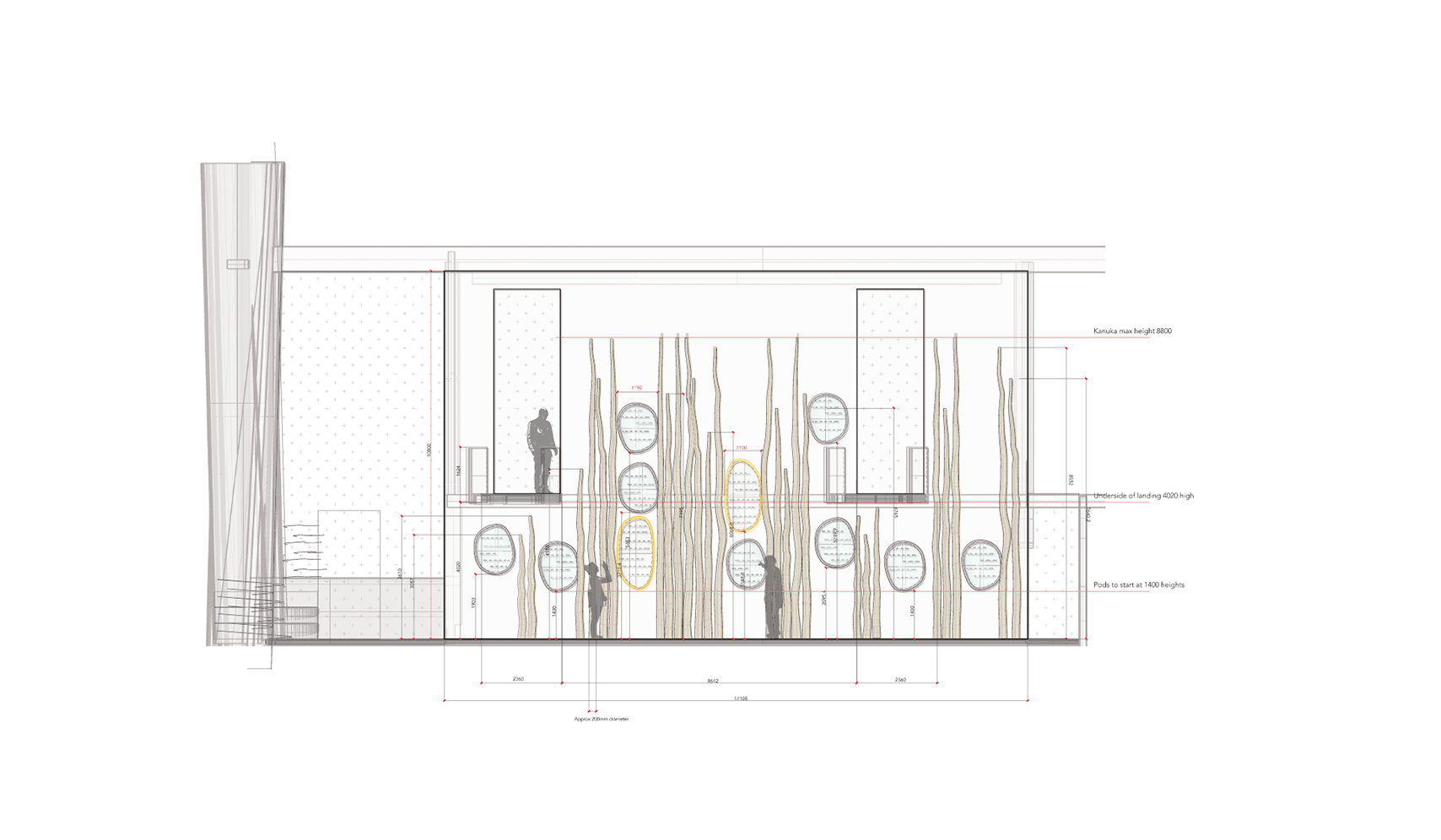

Ko Te Kihikihi Taku IngoaGovett Brewster Art Gallery

Ironclad BambooBamboo lids and Packaging

OrbitremoteA new frontier in remote audio control

Rotoiti BathMinimal aesthetic, compound curvature bathtub

BrevilleA selection of projects

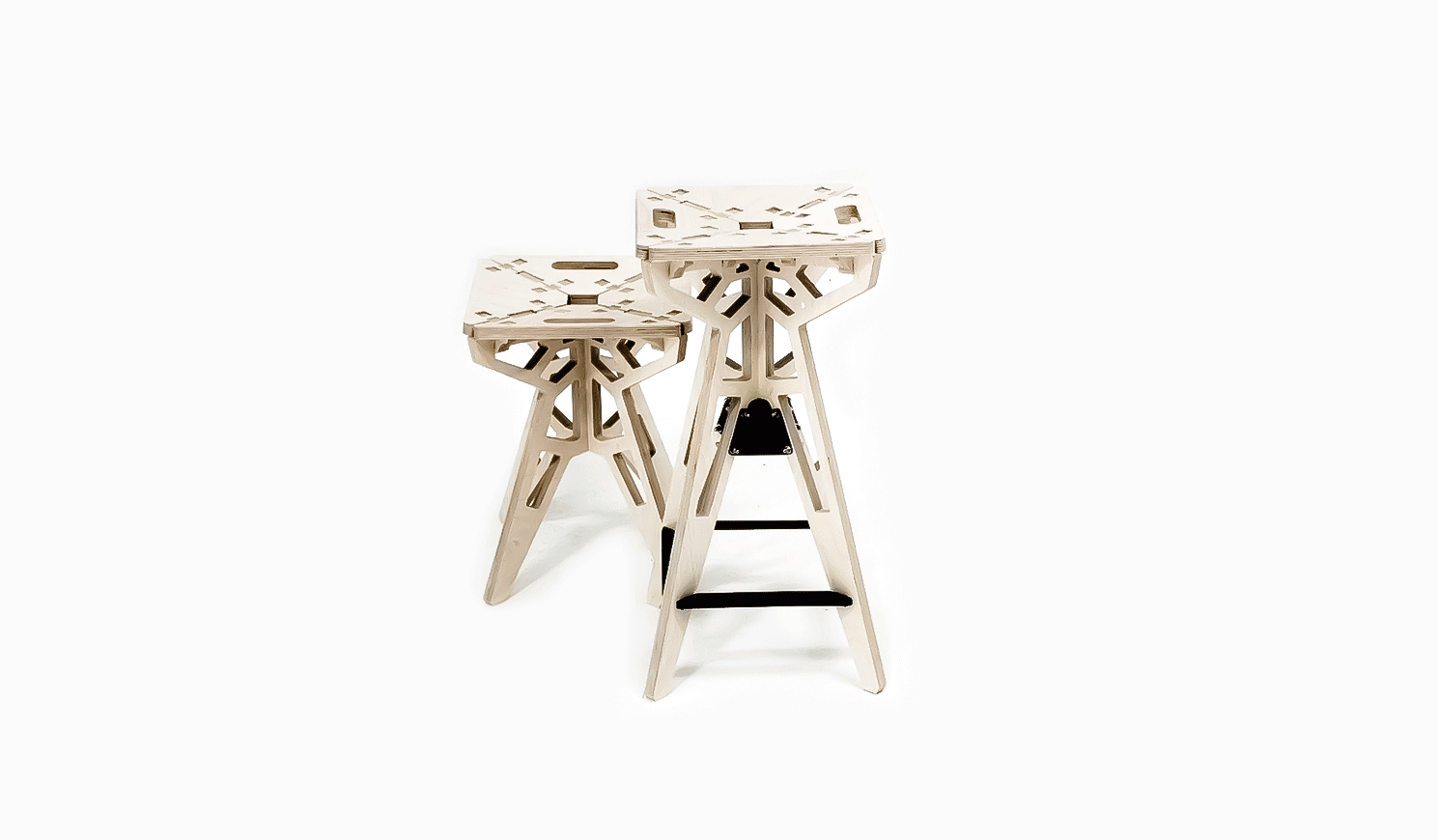

Space stoolsCNC cut stools

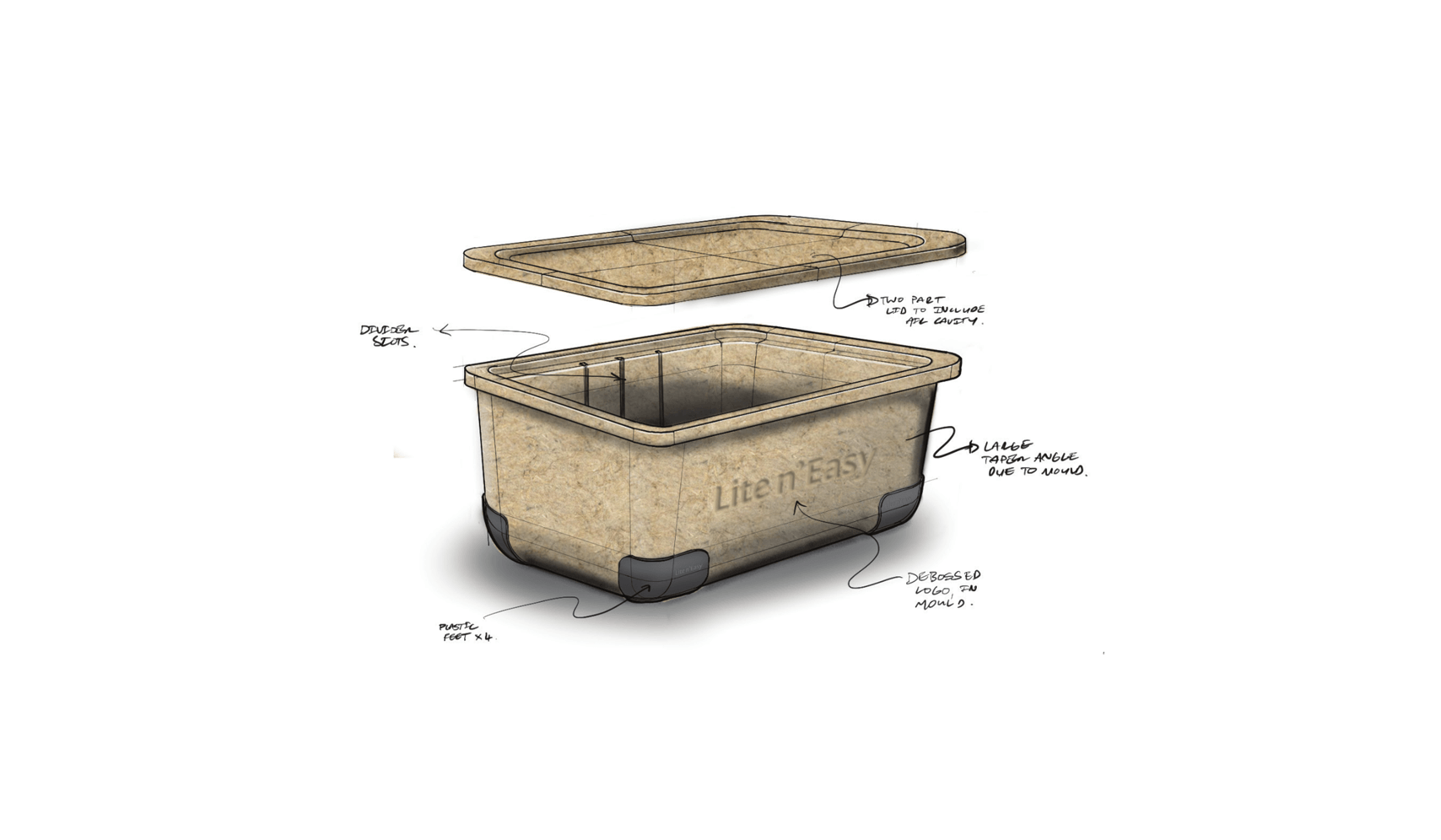

ThermoguardSustainable and re-useable food box

CEO SuiteChildrens desk and chair

Te MoungaCultural history exhibit

Gallipoli: The Scale of our WarExhibition furniture build

P70wAll in one soundbar

Meet the localsWellington zoo design and build

PK-01Portable kitchen

Maples kennelFlat pack dog kennel

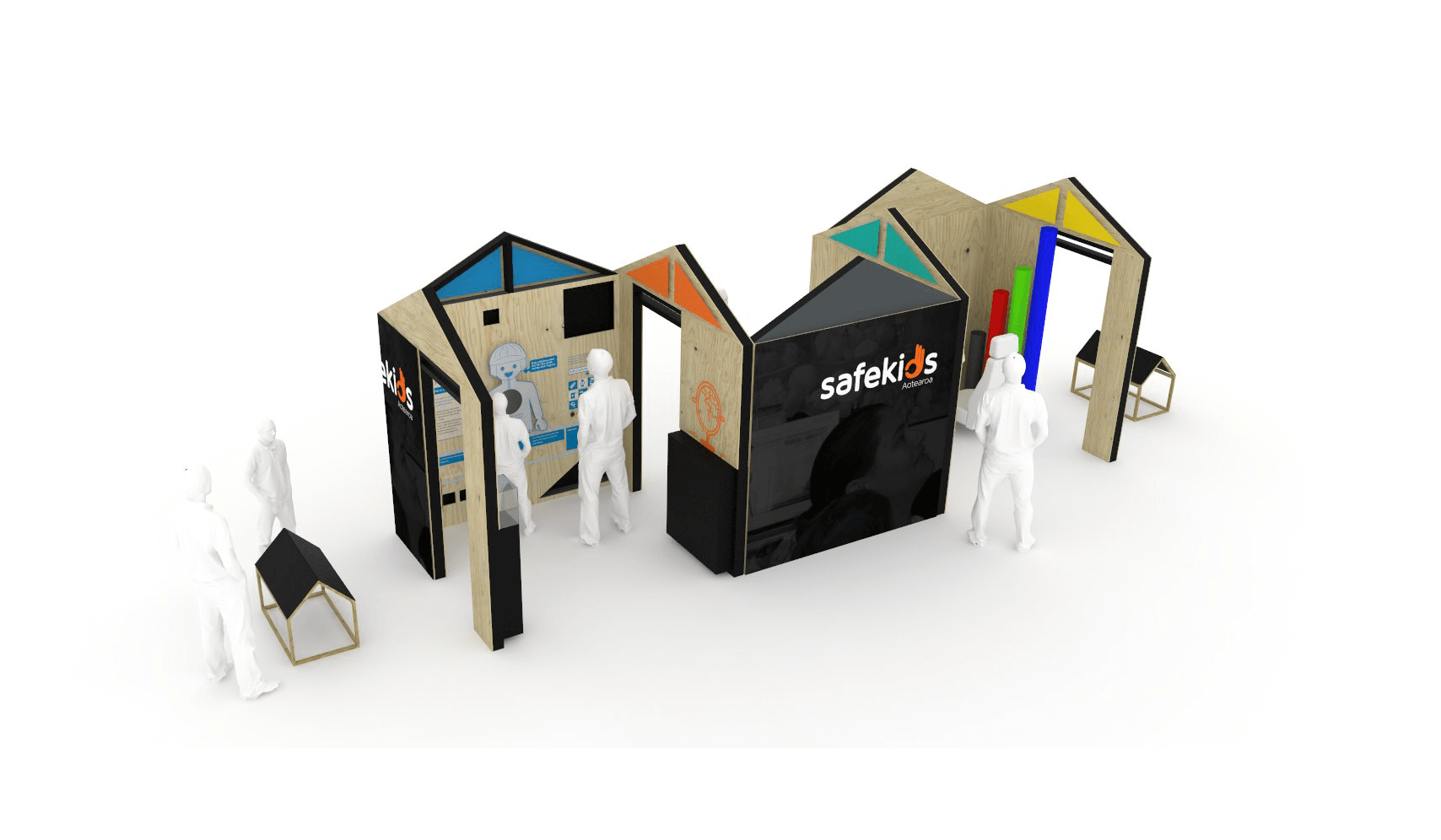

SafeKids AotearoaTouring popup exhibition

Barnaby Ward Design

5x Central Road, Kingsland

Auckland, 1021, NZ

© 2026

Book a Call

Book a Call Instagram.

Instagram. linkedin.

linkedin.