Creating better re-use for food delivery.

Project: Freelance

Disciplines: Industrial Design

Client: Thermoguard

Year: 2021

Project: Freelance

Disciplines: Industrial Design

Client: Thermoguard

Year: 2021

Project: Freelance

Disciplines: Industrial Design

Client: Thermoguard

Year: 2021

Project: Freelance

Disciplines: Industrial Design

Client: Thermoguard

Year: 2021

Project: Freelance

Disciplines: Industrial Design

Client: Thermoguard

Year: 2021

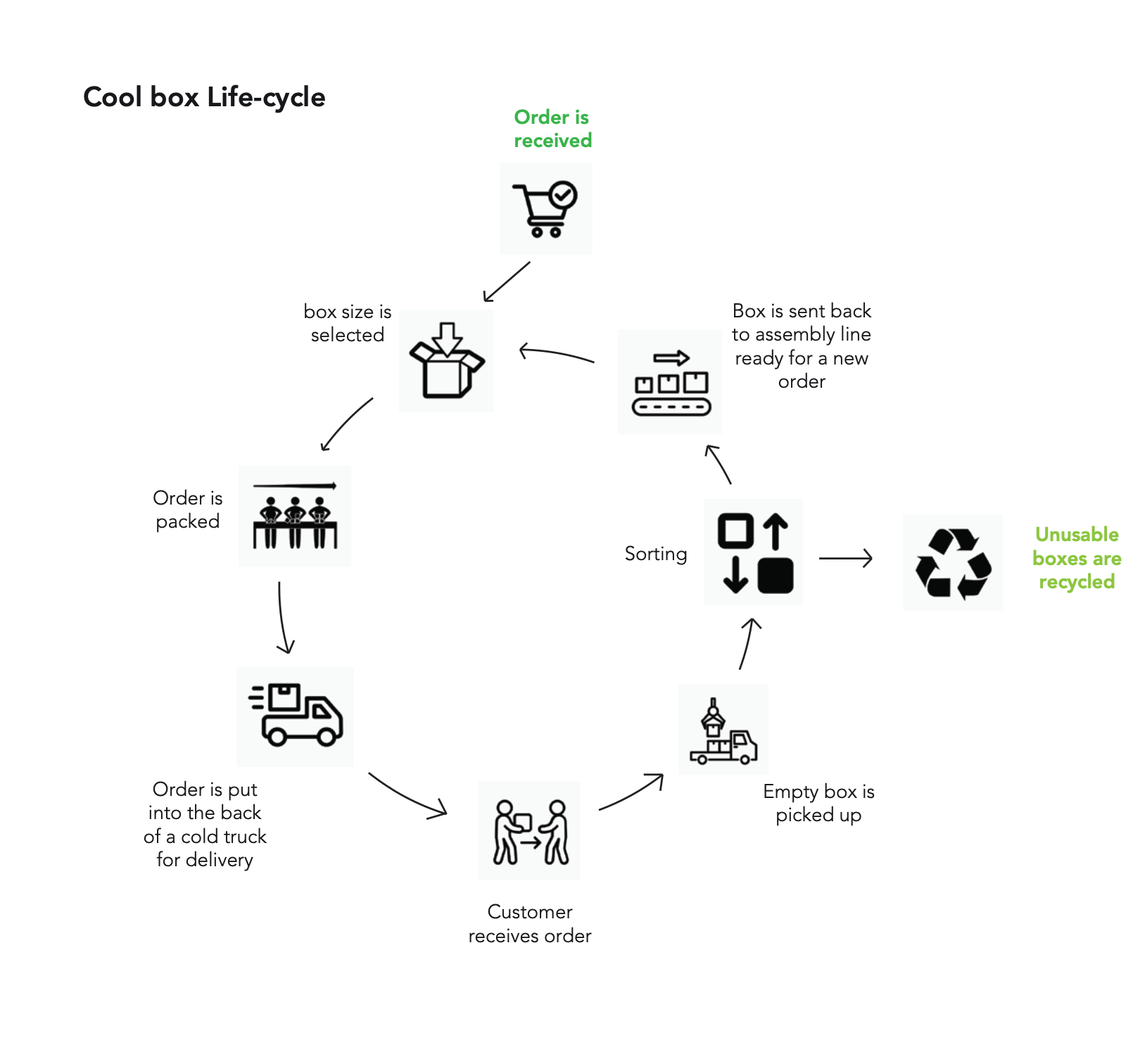

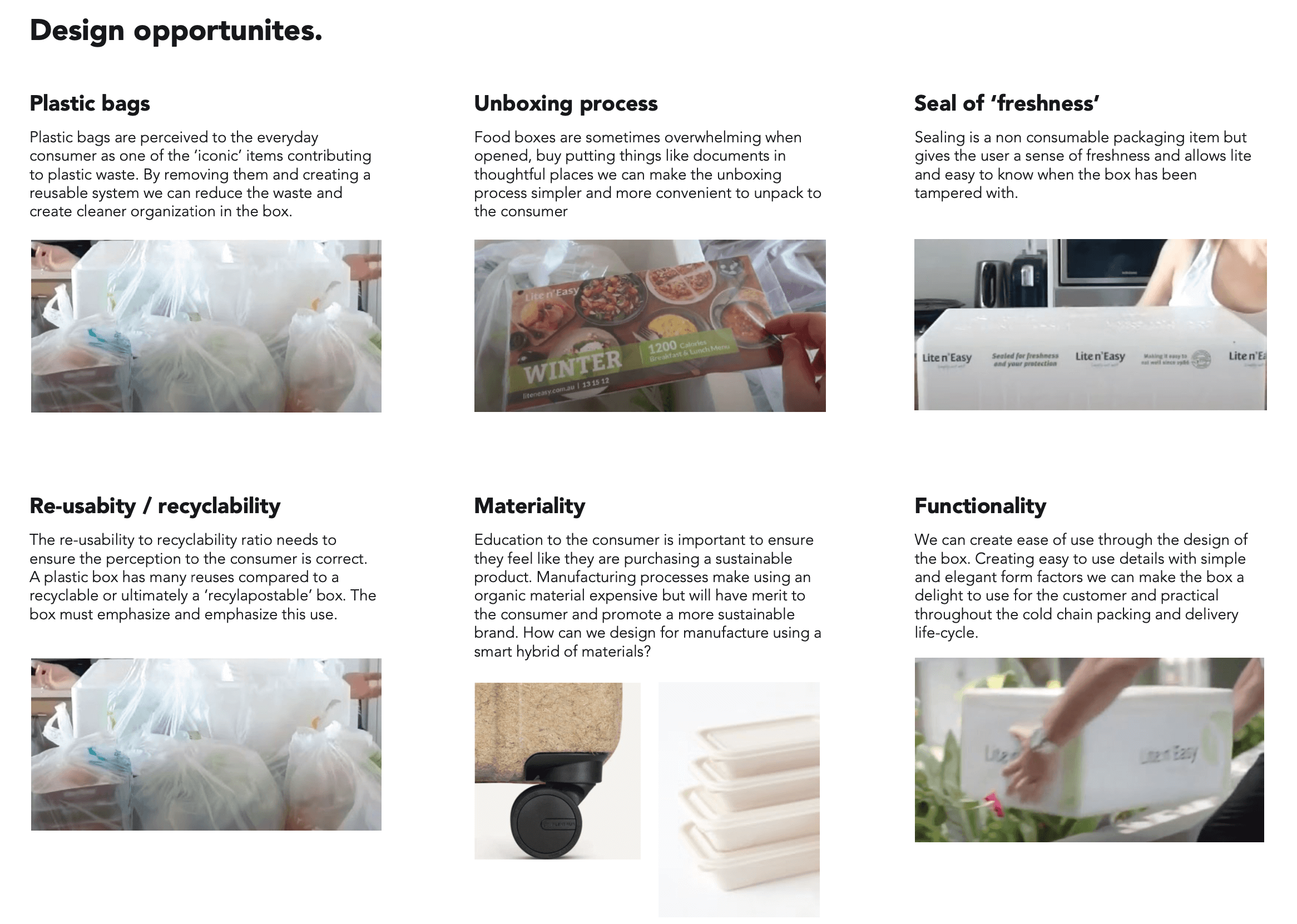

The client was after a reusable cool box for their food delivery service. The overall focus was to move away from poly boxes and create a more sustainable option that allows for reuse and recyclability.

This project was a quick 3 day exploration and deep dive into the look and feel of the product based on the material choices Thermogard have proposed. During this process, I have kept in mind how the end user will perceive the product whilst considering functionality and longevity.

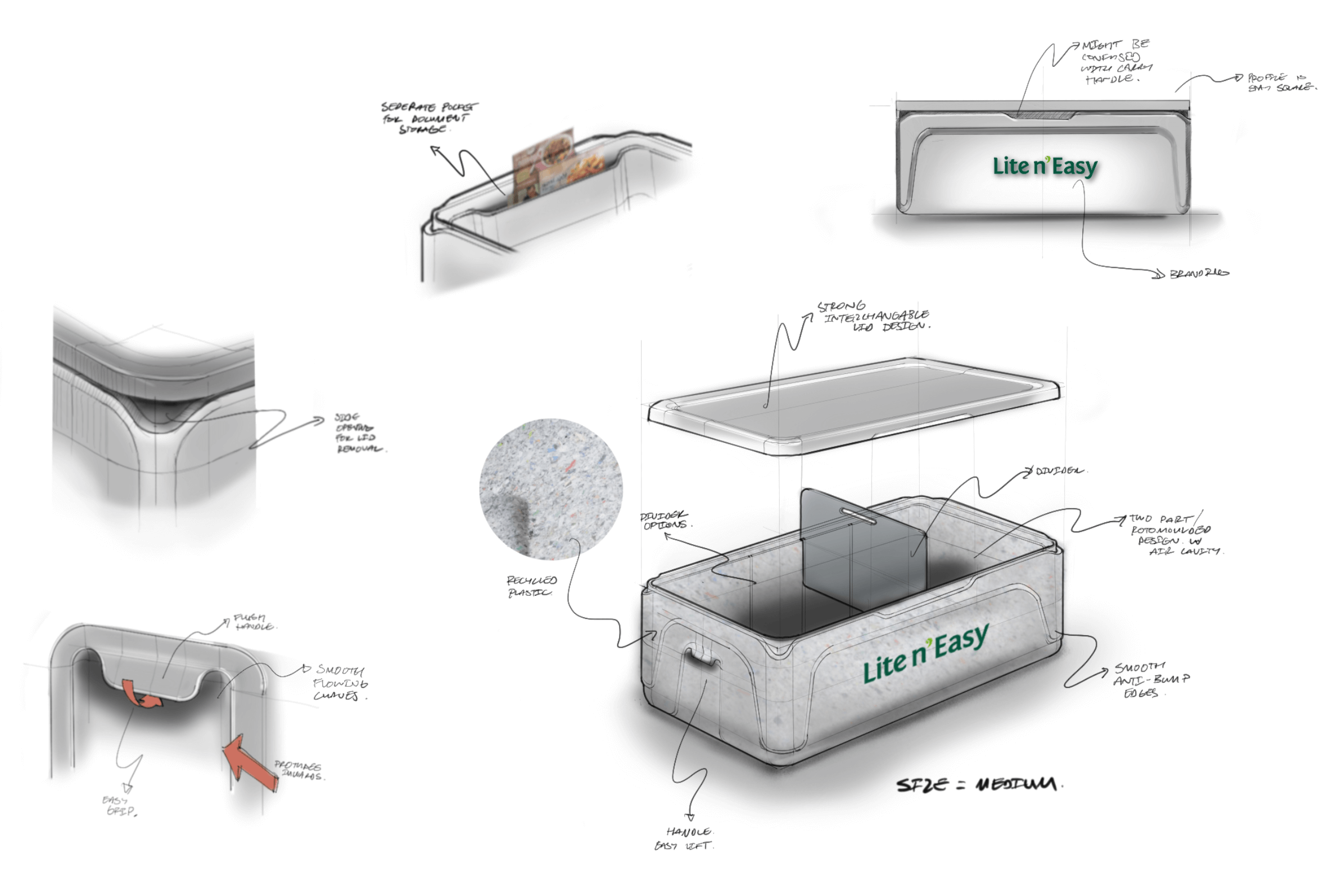

Concept - PET box

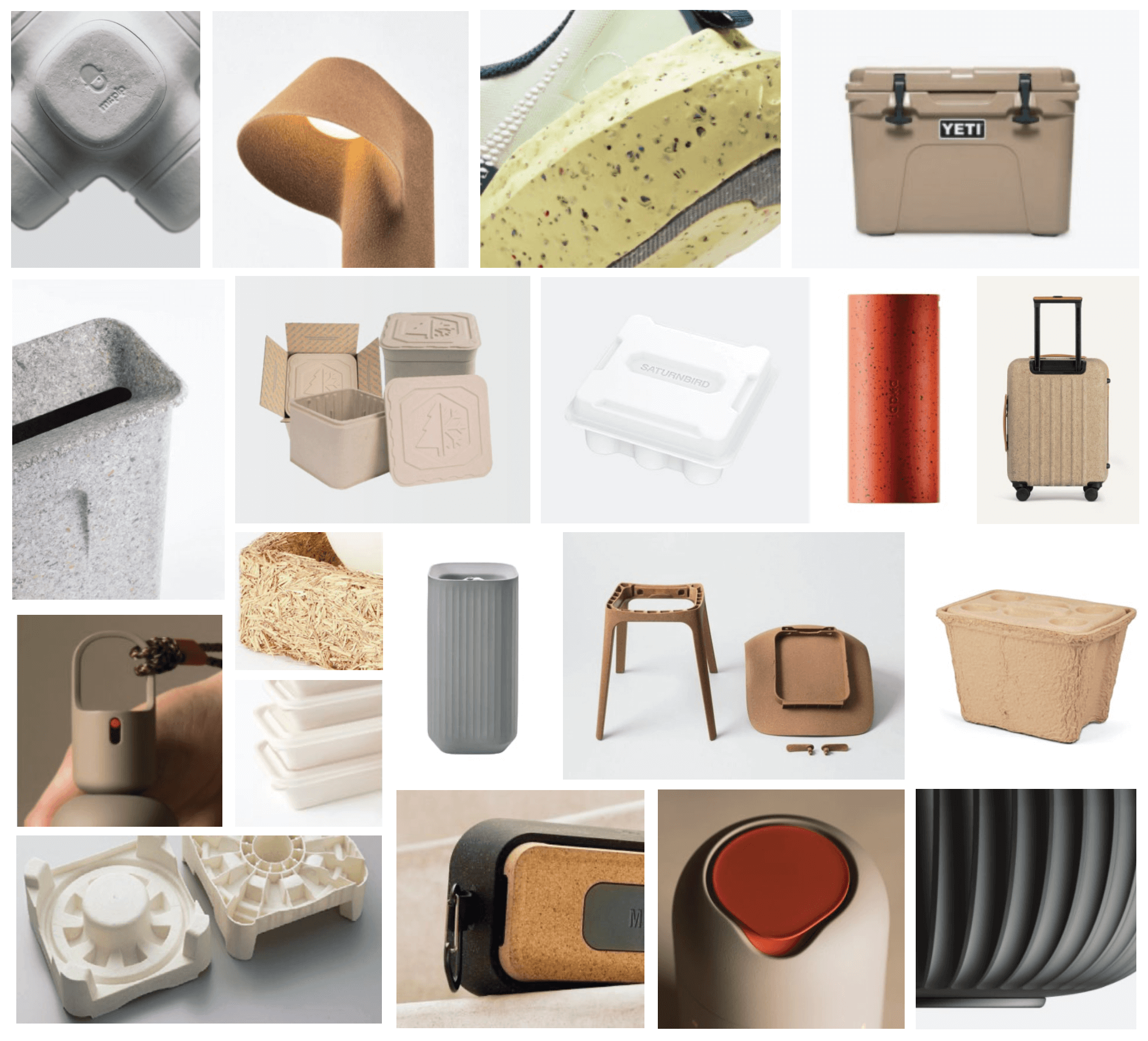

The main benefit of a PET /HDPE box is re-usability.

A plastic box can offer a huge amount of durability and allows Lite n Easy to re use and recycle at the end of its life being that it is made from a thermoplastic.

Portraying the sustainable element to the customer is difficult but by using CMF (colour material finish) we can add value here. Perception of recycled plastic textures (different colours) and plastics cleaned up from ocean waste etc.

Moulded plastic also allows us to add function to the boxes like storage for documents and ergonomic handholds while providing excellent thermal retention. However this may become such a good ‘esky’ that consumers will want to use it for personal reasons therefore lowering return rates.

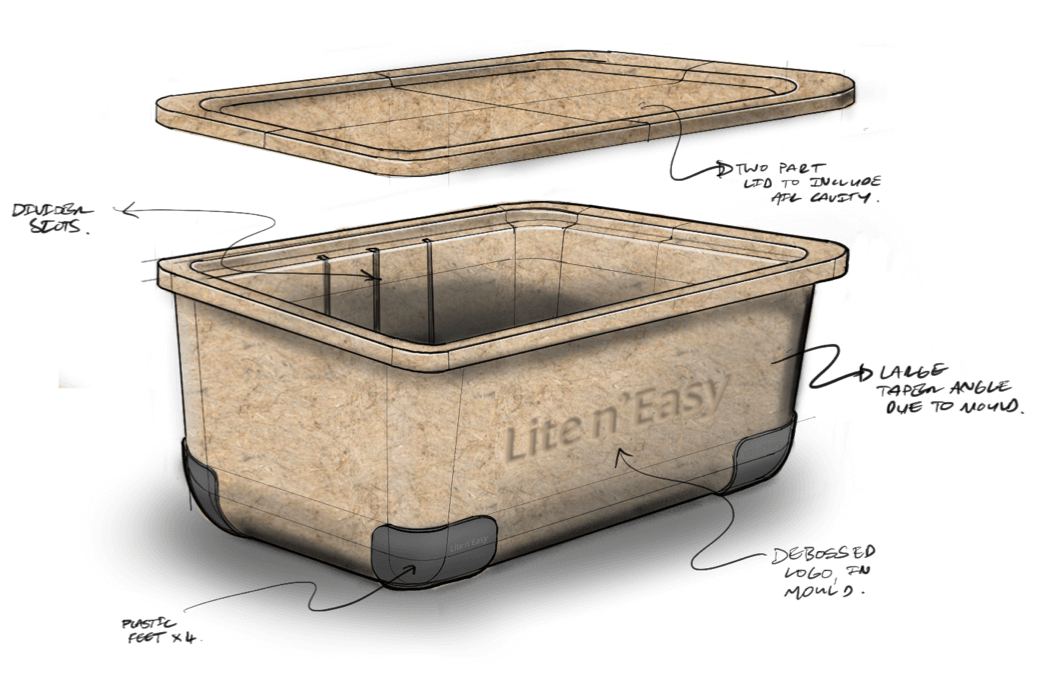

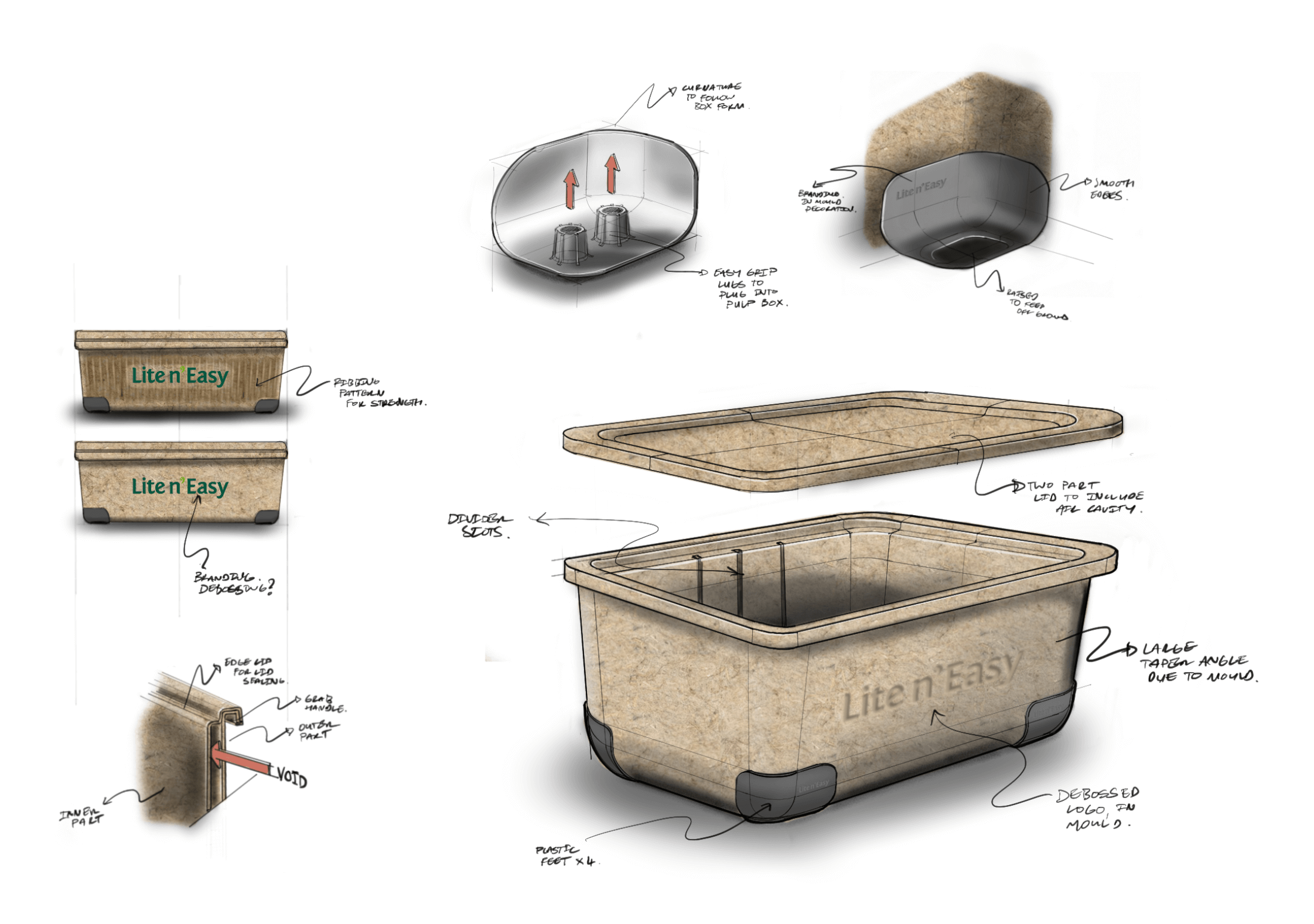

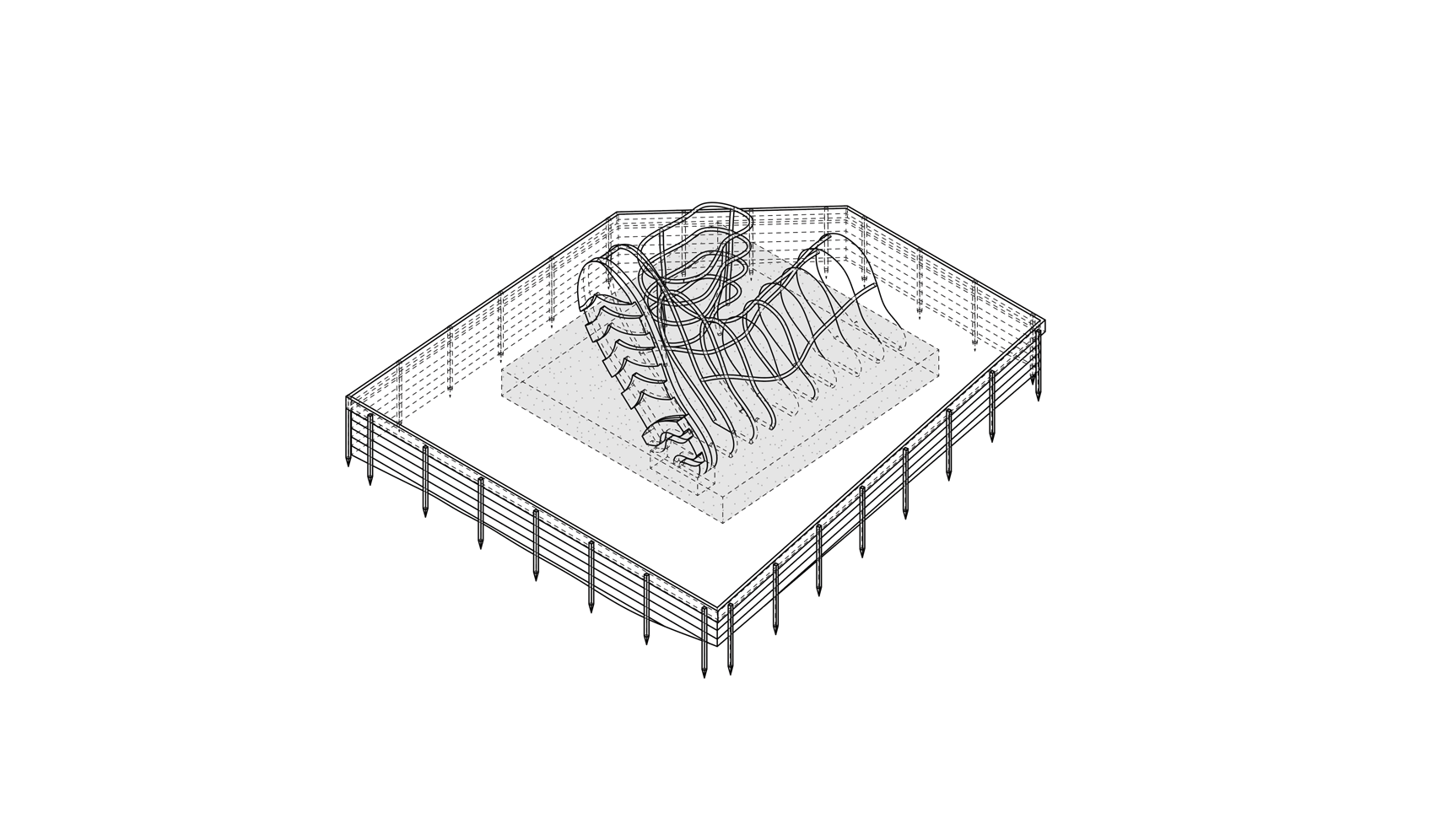

Concept - Pulp / plastic hybrid

This concept focuses on the main construction fo the box being a moulded fibre pulp box, though this design lends itself to similar materials as they share the same manufacturing process. Typically these products are becoming more common in the industry so manufacturing and mould making technologies are more accessible and becoming cheaper.

With a two part construction for both the Main box and the lid we can create air cavities which are vital to providing thermal insulation. The strength and rigidity of the box can meet requirements with careful design consideration.

A common problem with the pulp boxes is waterproofing and lifespan of the product. When considering re-usability rate the concept of plastic feet help keep the box off the ground and protect the edges. These plastic parts can then be removed and re-used with a new box and the main box will be recycled (or composted).

.

Other projects.

Trailtech Battery12v Trail camera Battery

Cast Iron LidsIronclad Enamelware Lids

RECONTrolling motor

The Oracle JetEspresso Machine

Air D1Luxury Loudspeaker

Hydration BottlePremium Reuseable Water Bottle

Retail CartPortable Retail Display Cart

Lowrance Eagle seriesFish Finder/chart plotter

Dock E30Studio Quality Compact Speaker

Resn labsSemi-permanent installation in Shenzhen China

HikoterraH4 Power System Visuals

NSX - UltrawideUltrawide marine display.

Jones JrMinimal multi-purpose task lamp

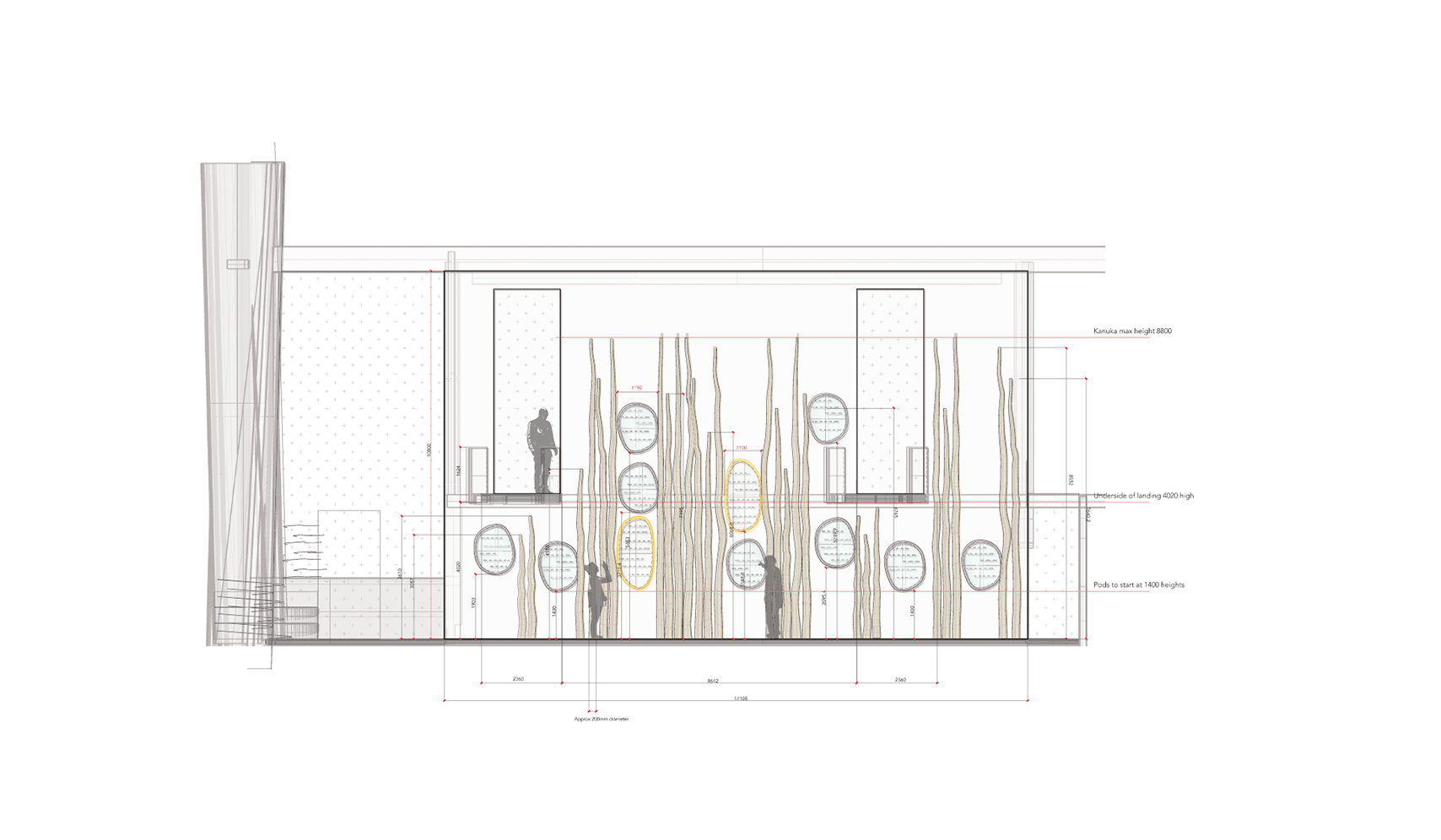

Ko Te Kihikihi Taku IngoaGovett Brewster Art Gallery

Ironclad BambooBamboo lids and Packaging

OrbitremoteA new frontier in remote audio control

Rotoiti BathMinimal aesthetic, compound curvature bathtub

BrevilleA selection of projects

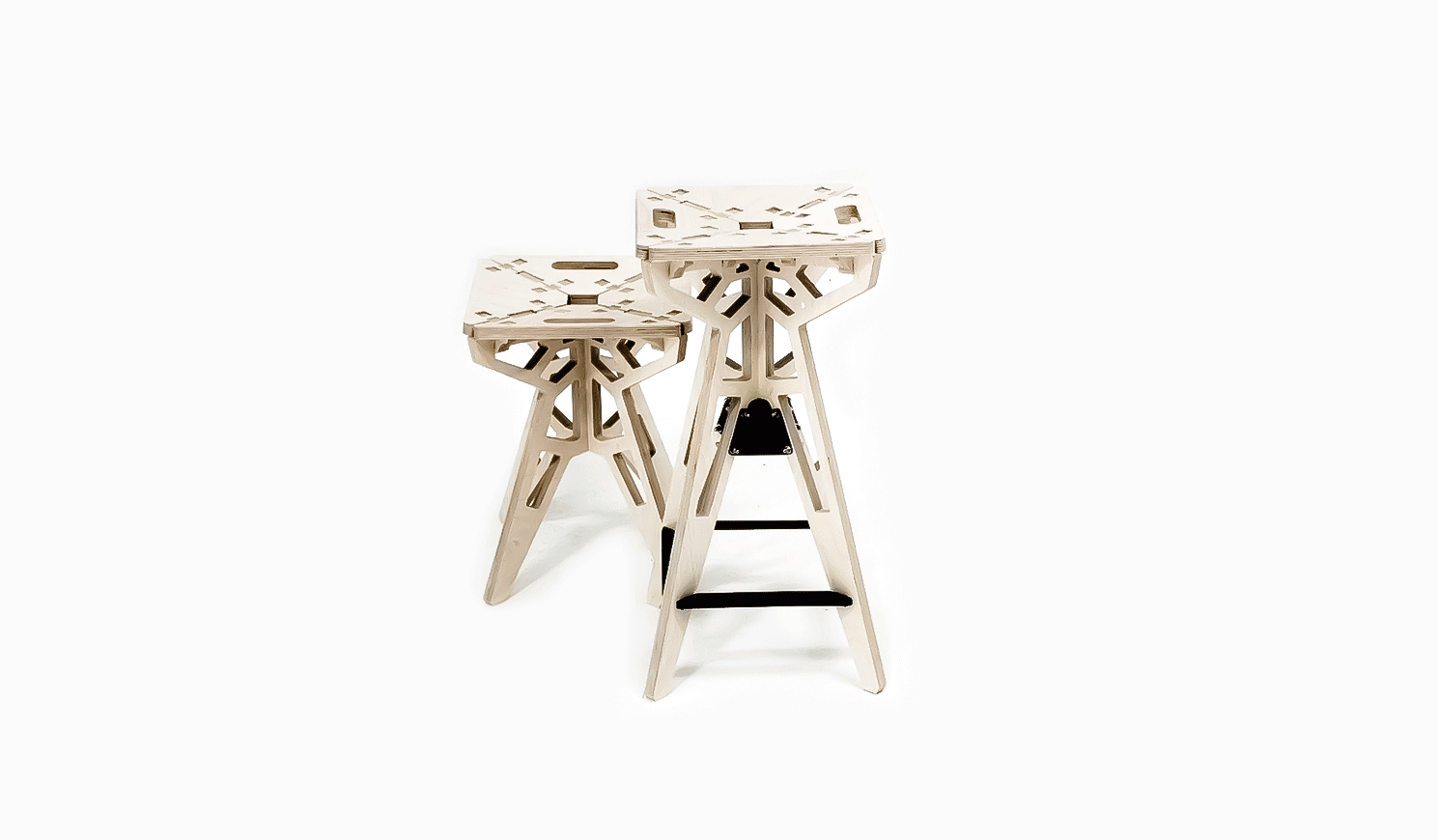

Space stoolsCNC cut stools

TVTRCompact soundbar

CEO SuiteChildrens desk and chair

Te MoungaCultural history exhibit

Gallipoli: The Scale of our WarExhibition furniture build

P70wAll in one soundbar

Meet the localsWellington zoo design and build

PK-01Portable kitchen

Maples kennelFlat pack dog kennel

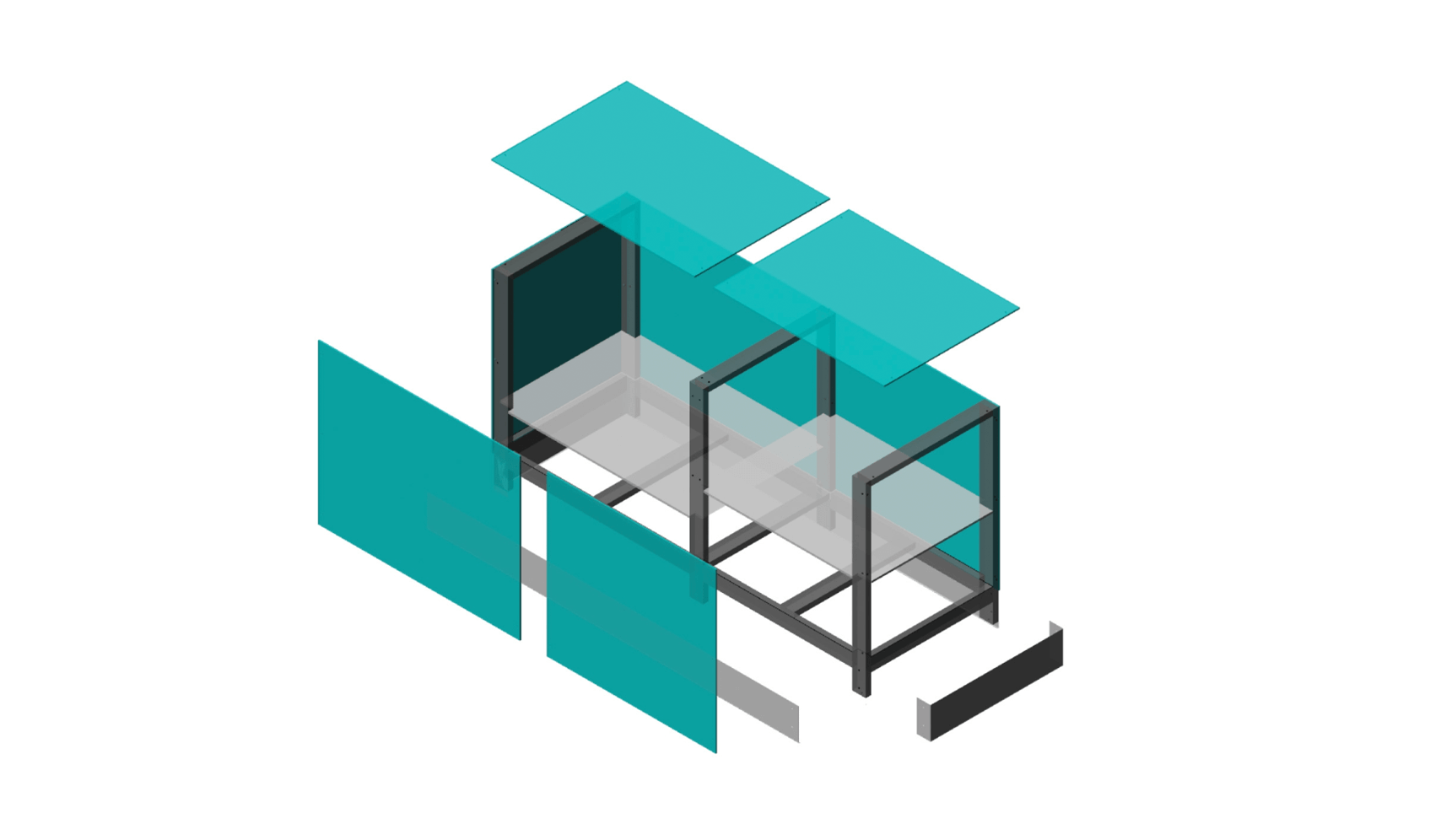

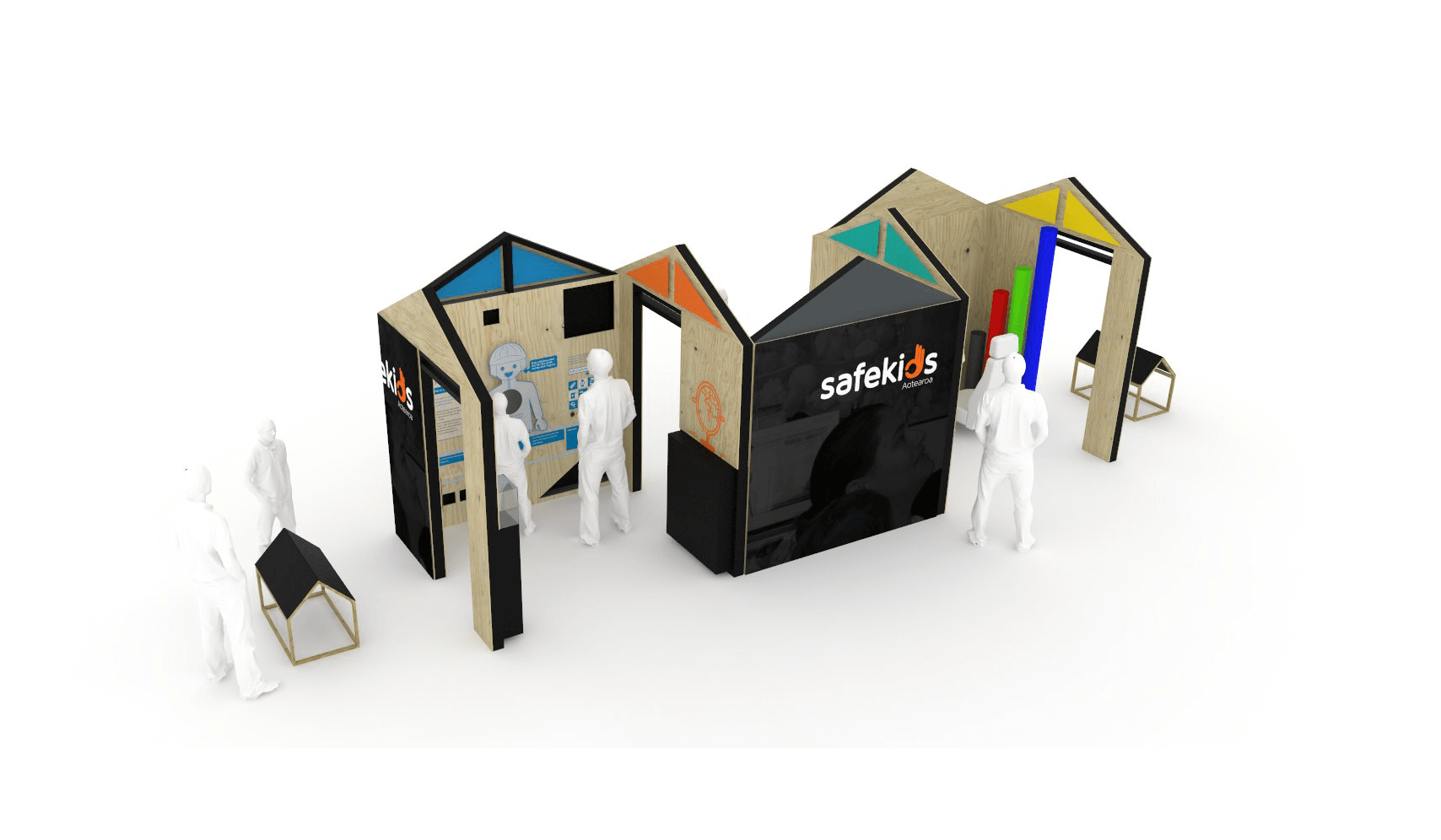

SafeKids AotearoaTouring popup exhibition

Barnaby Ward Design

5x Central Road, Kingsland

Auckland, 1021, NZ

© 2026

Book a Call

Book a Call Instagram.

Instagram. linkedin.

linkedin.