Most product teams do not fail because of a lack of ideas. They fail because decisions arrive too late, priorities drift, and design intent gets diluted as projects move toward manufacturing. The work below is written from a practical consultancy perspective in New Zealand, working with founders, product managers, and engineering teams that need clarity and momentum.

In this article, I break down from sketch to shelf, a practical product development pathway from a delivery perspective: what to prioritise, what to avoid, and how to keep teams aligned when trade-offs become real.

Why this matters now

Industrial design teams are expected to move faster while still reducing risk. That combination only works when the process is explicit. You need clear decision points, practical prototypes, and accountability across design, engineering, and commercial teams. In my experience, projects slow down when everyone is waiting for a perfect answer. Momentum returns when you define what must be true at each stage, then test those assumptions with the lightest method that still gives credible evidence.

Start with constraints, not style

Early concept work should map constraints before it chases visual novelty. Constraints include target cost, production volume, supply chain realities, performance requirements, regulatory considerations, and servicing expectations. If these are undefined, teams often approve concepts that look strong in reviews but collapse under engineering detail. A better pattern is to publish a one-page design brief with non-negotiables and acceptable trade-offs. That document becomes the alignment tool for design reviews and supplier conversations.

Build a decision cadence

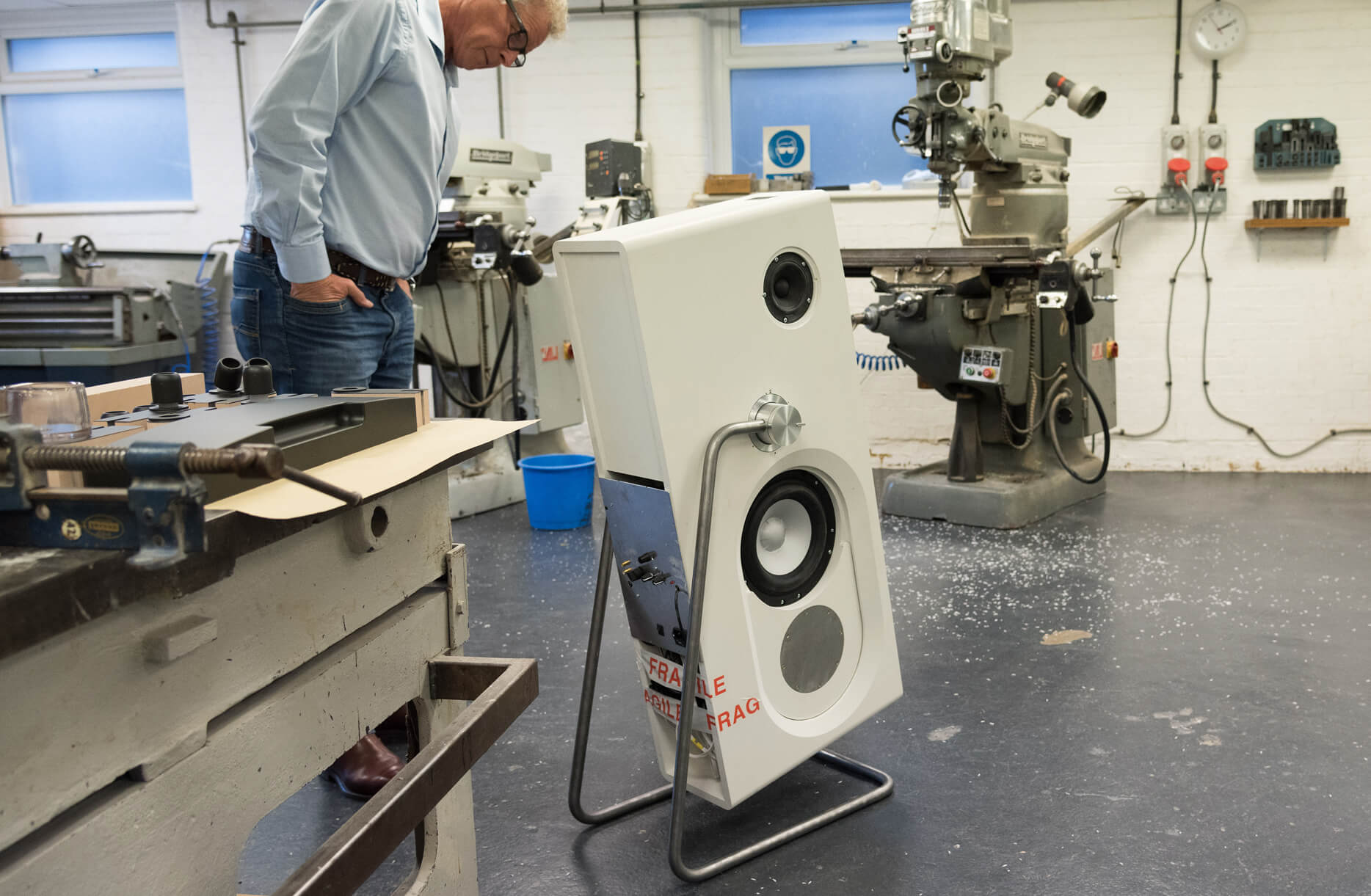

Project reference: DOCK E30.

Most teams run too many meetings and make too few decisions. Establish a predictable cadence where each review has a stated purpose: direction selection, feasibility checkpoint, prototype readout, or pre-tooling sign-off. Decision ownership should be explicit. When roles are vague, unresolved questions drift between teams and become expensive later. Keep a live issue register with owner, due date, and impact. This is simple, but it is one of the highest-leverage habits for keeping product development moving.

Prototype with intent

Prototyping should answer specific questions. A rough foam model can resolve proportion and ergonomics. A 3D print can validate fit and assembly logic. A limited electronics mule can test thermal behaviour and control interactions. Treat each prototype as an experiment with a hypothesis and success criteria. If a prototype does not change a decision, it is theatre. If it resolves one critical risk, it has paid for itself quickly. This mindset is essential for practical product development and credible planning.

Operational handover and launch readiness

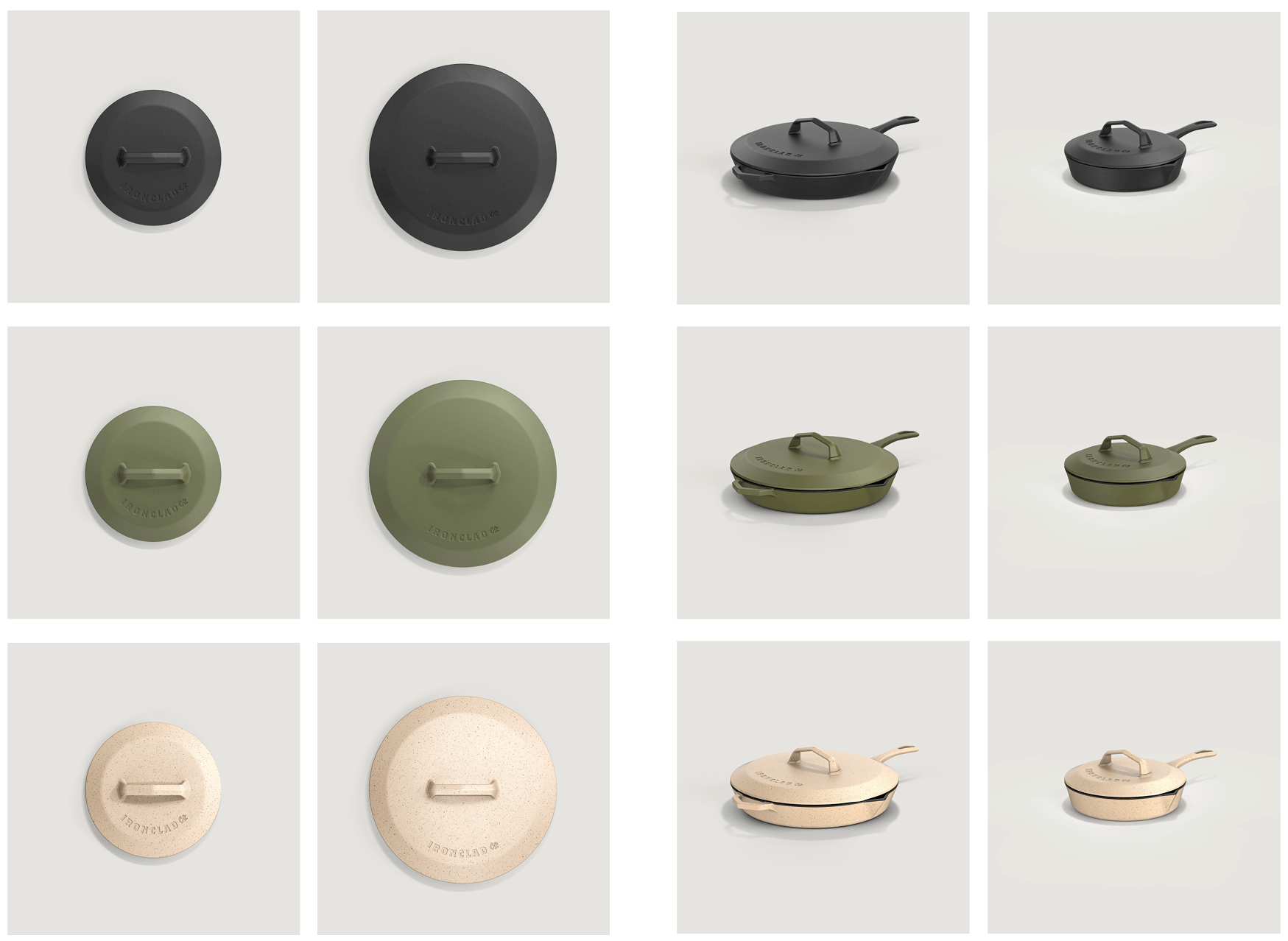

Good design handover is not just CAD export. It includes annotated intent, tolerance strategy, material rationale, assembly priorities, known risks, and expected quality standards. Marketing and sales teams also benefit when visualisation assets are prepared early, because launch content can evolve in parallel with final engineering. The goal is to avoid the late-stage scramble where technical and commercial deliverables are fighting for time. A calm handover process usually indicates the project has been managed with discipline.

Practical takeaways

Document assumptions at the start. Review them every fortnight. Tie prototype activity to decisions, not to optics. Bring suppliers into the loop earlier than feels comfortable. Keep design and engineering communication visible and written. Invest in clean handover packs. These are not glamorous steps, but they are what separate fragile concepts from products that ship reliably. If your team is under schedule pressure, these practices become even more valuable because they prevent rework and keep confidence high.

A checklist you can use this week

- Confirm scope boundaries and required outcomes in writing.

- Define what must be tested before committing to tooling or long-lead spend.

- Keep one owner responsible for closing each open risk.

- Use visual communication aggressively so non-technical stakeholders stay aligned.

- Capture decisions with context so new team members can ramp quickly.

- Connect design outputs to launch readiness, not just internal approval.

Related projects and services

Final note

Strong product outcomes are rarely the result of one brilliant workshop. They come from repeated, disciplined execution across many small decisions. When teams adopt a transparent process and keep design intent connected to engineering and commercial realities, delivery becomes calmer and more predictable. That is ultimately the goal: not more complexity, but better clarity at each stage.

If you are planning a new programme and want a practical second opinion, start with the Services page and then review related case studies in Projects. The strongest projects do not rely on luck. They rely on clear choices made early, tested quickly, and documented properly before production.

Last updated: 2026-01-08

Book a Call

Book a Call Instagram.

Instagram. linkedin.

linkedin.