Redevolping Breville’s top Espresso offering.

Redevolping Breville’s top Espresso offering.

Redevolping Breville’s top Espresso offering.

Redevolping Breville’s top Espresso offering.

Redevolping Breville’s top Espresso offering.

Project: BKE900

Disciplines:

Industrial Design

Mechanical Design

Year: 2019

Project: BKE900

Disciplines:

Industrial Design

Mechanical Design

Year: 2019

Project: BKE900

Disciplines:

Industrial Design

Mechanical Design

Year: 2019

Project: BKE900

Disciplines:

Industrial Design

Mechanical Design

Year: 2019

Project: BKE900

Disciplines:

Industrial Design

Mechanical Design

Year: 2019

The Oracle Jet was envisioned as a complete reimagination of Breville’s top-tier espresso machine. The project introduced a new technological foundation, integrating an advanced auto-tamper ‘augur’ system and a redesigned hydraulic assembly to elevate performance and user experience.

The Oracle Jet was envisioned as a complete reimagination of Breville’s top-tier espresso machine. The project introduced a new technological foundation, integrating an advanced auto-tamper ‘augur’ system and a redesigned hydraulic assembly to elevate performance and user experience.

The Oracle Jet was envisioned as a complete reimagination of Breville’s top-tier espresso machine. The project introduced a new technological foundation, integrating an advanced auto-tamper ‘augur’ system and a redesigned hydraulic assembly to elevate performance and user experience.

The Oracle Jet was envisioned as a complete reimagination of Breville’s top-tier espresso machine. The project introduced a new technological foundation, integrating an advanced auto-tamper ‘augur’ system and a redesigned hydraulic assembly to elevate performance and user experience.

The Oracle Jet was envisioned as a complete reimagination of Breville’s top-tier espresso machine. The project introduced a new technological foundation, integrating an advanced auto-tamper ‘augur’ system and a redesigned hydraulic assembly to elevate performance and user experience.

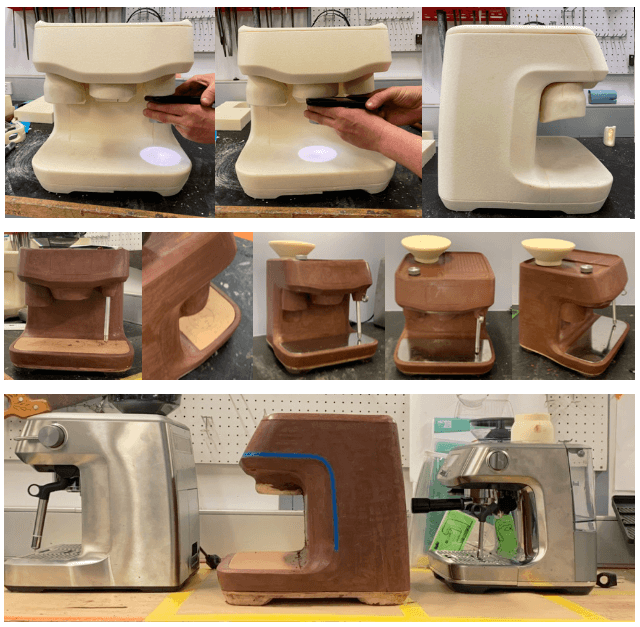

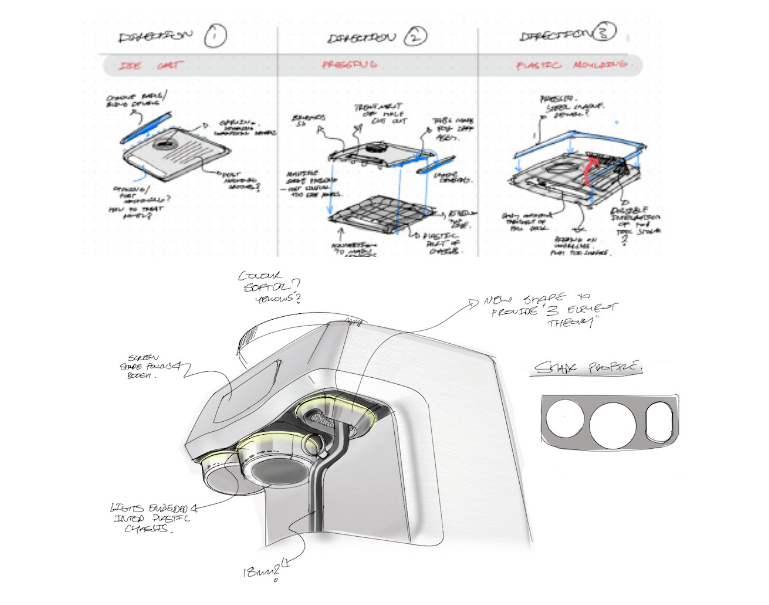

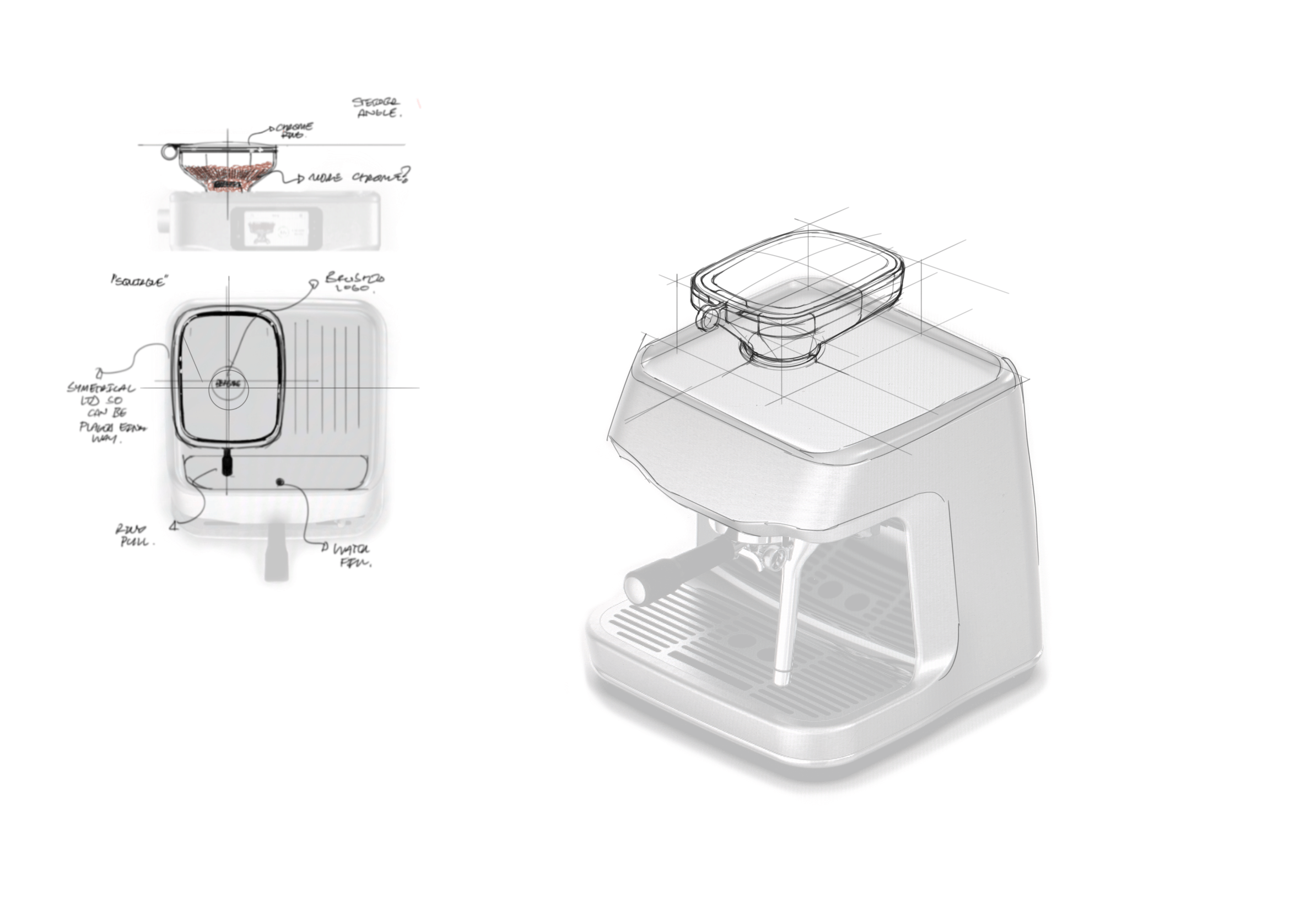

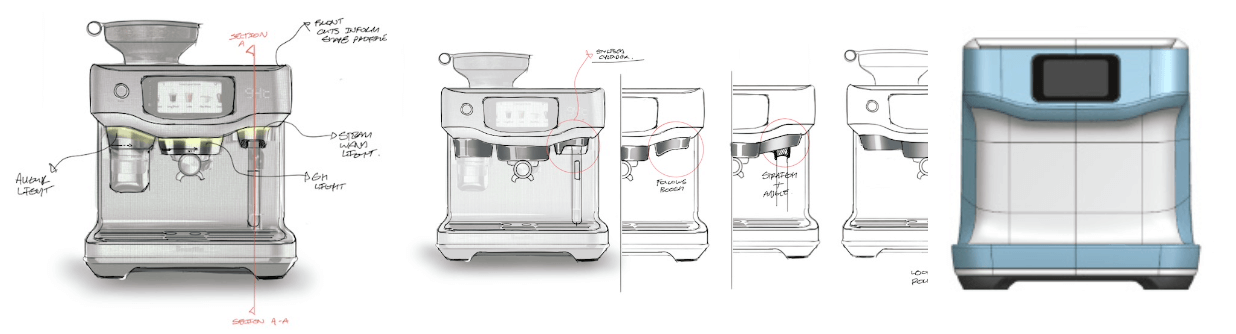

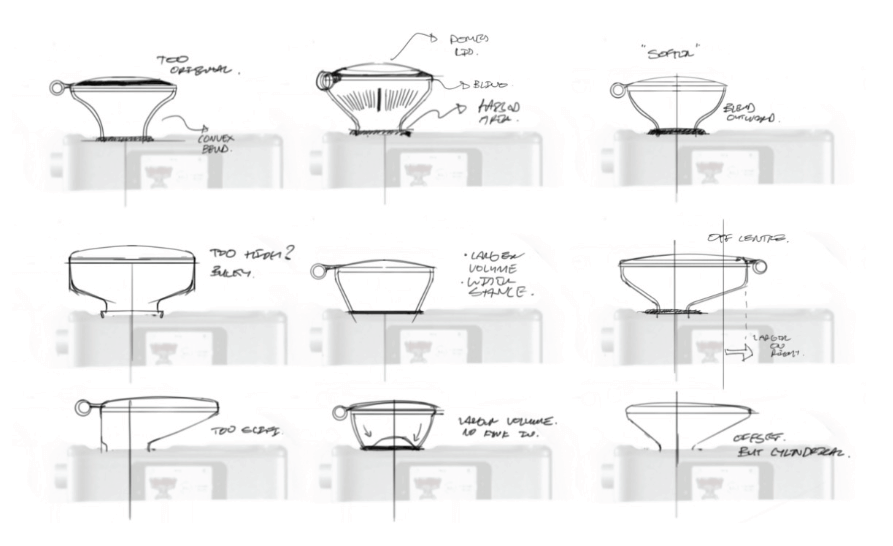

ID development.

The design process focused on refining both the machine’s overall form and detailed components. Clay modelling and foam prototypes enabled exploration of shape and proportion. These physical models were 3D scanned, transitioning into digital CAD environments to inform the development of a fully machined “looks-like” prototype. This prototype was critical in advancing through Breville’s stage gate review process.

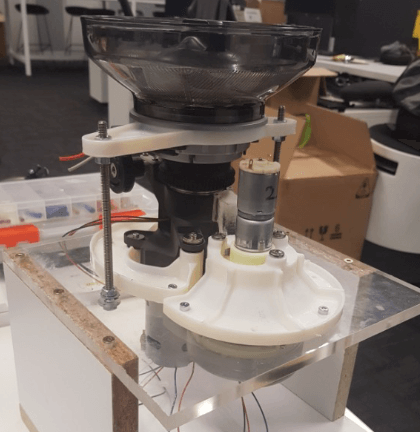

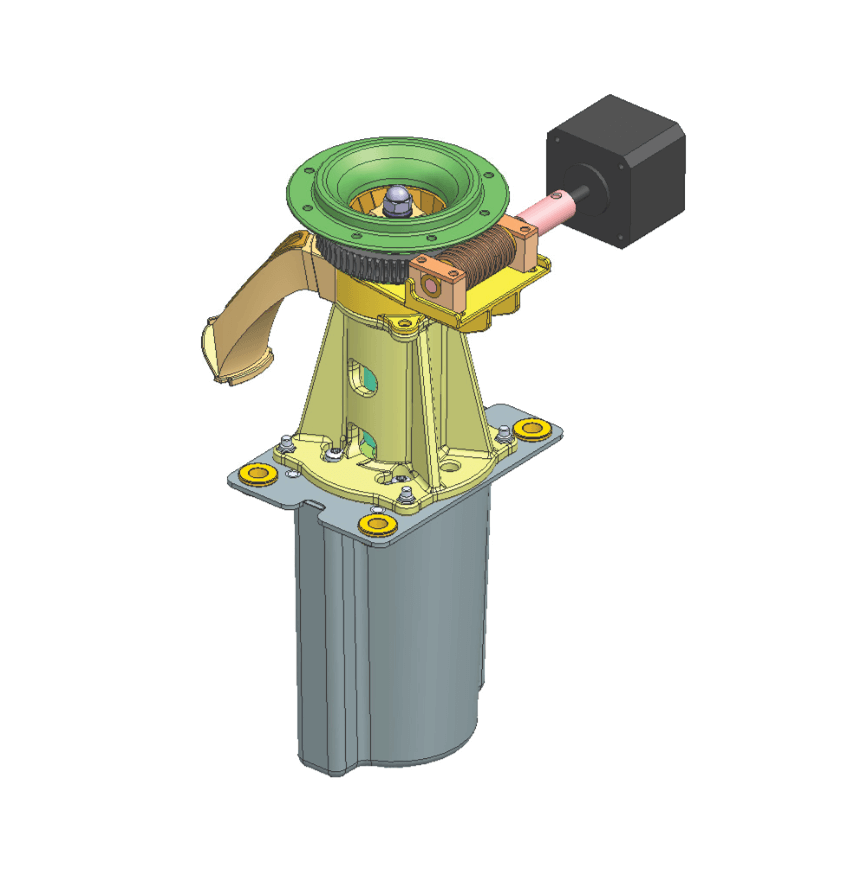

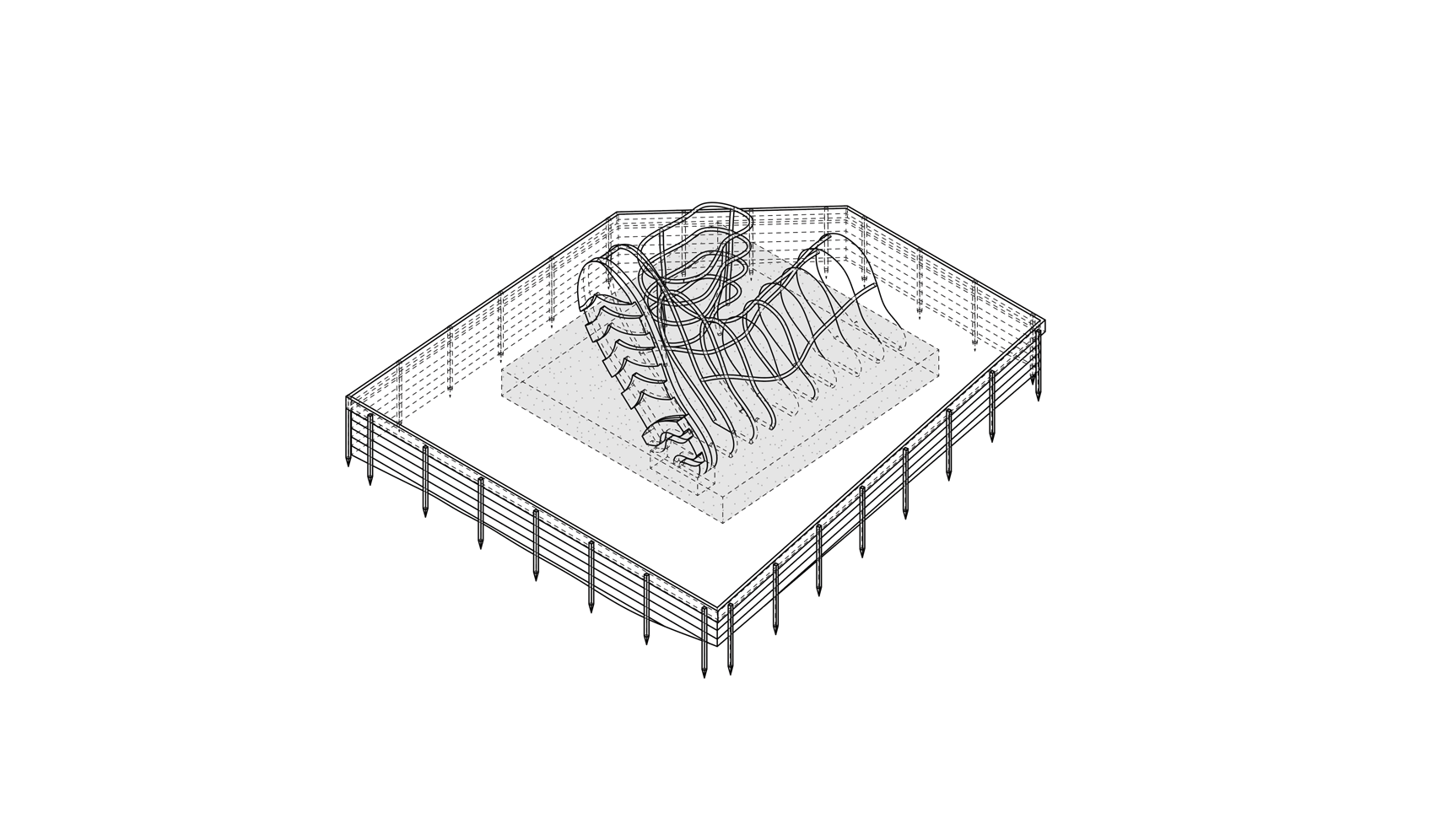

Rig building

Rig development played a pivotal role in validating design and engineering solutions. Sub-system rigs were built and iteratively tested to demonstrate feasibility and functionality at each stage gate, ensuring confidence in performance before advancing.

Rig building

Rig development played a pivotal role in validating design and engineering solutions. Sub-system rigs were built and iteratively tested to demonstrate feasibility and functionality at each stage gate, ensuring confidence in performance before advancing.

Rig building

Rig development played a pivotal role in validating design and engineering solutions. Sub-system rigs were built and iteratively tested to demonstrate feasibility and functionality at each stage gate, ensuring confidence in performance before advancing.

Rig building

Rig development played a pivotal role in validating design and engineering solutions. Sub-system rigs were built and iteratively tested to demonstrate feasibility and functionality at each stage gate, ensuring confidence in performance before advancing.

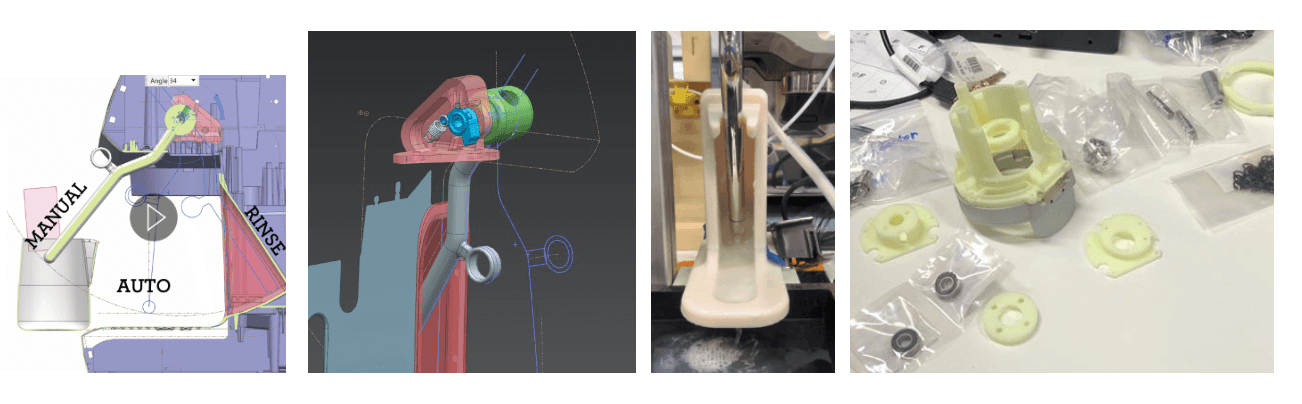

Prototype testing

A series of prototypes were created to rigorously test design concepts and mechanical systems. This iterative process embraced a “fail-to-succeed” mentality, allowing the team to identify and resolve challenges before progressing to production.

Prototype testing

A series of prototypes were created to rigorously test design concepts and mechanical systems. This iterative process embraced a “fail-to-succeed” mentality, allowing the team to identify and resolve challenges before progressing to production.

Prototype testing

A series of prototypes were created to rigorously test design concepts and mechanical systems. This iterative process embraced a “fail-to-succeed” mentality, allowing the team to identify and resolve challenges before progressing to production.

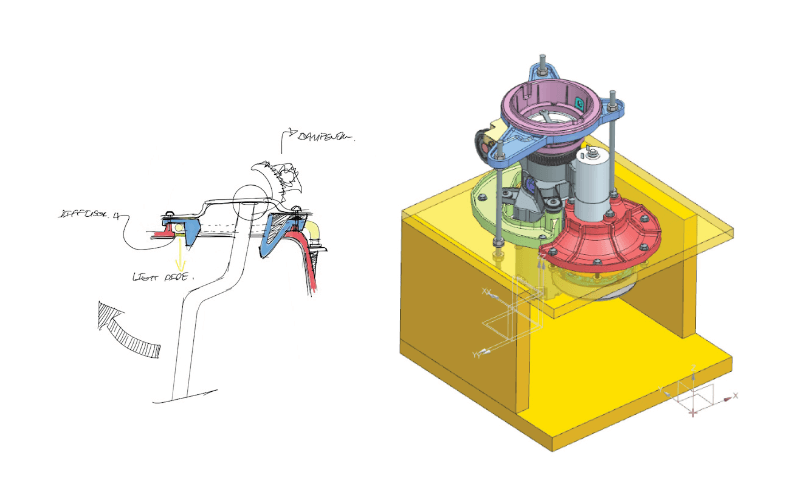

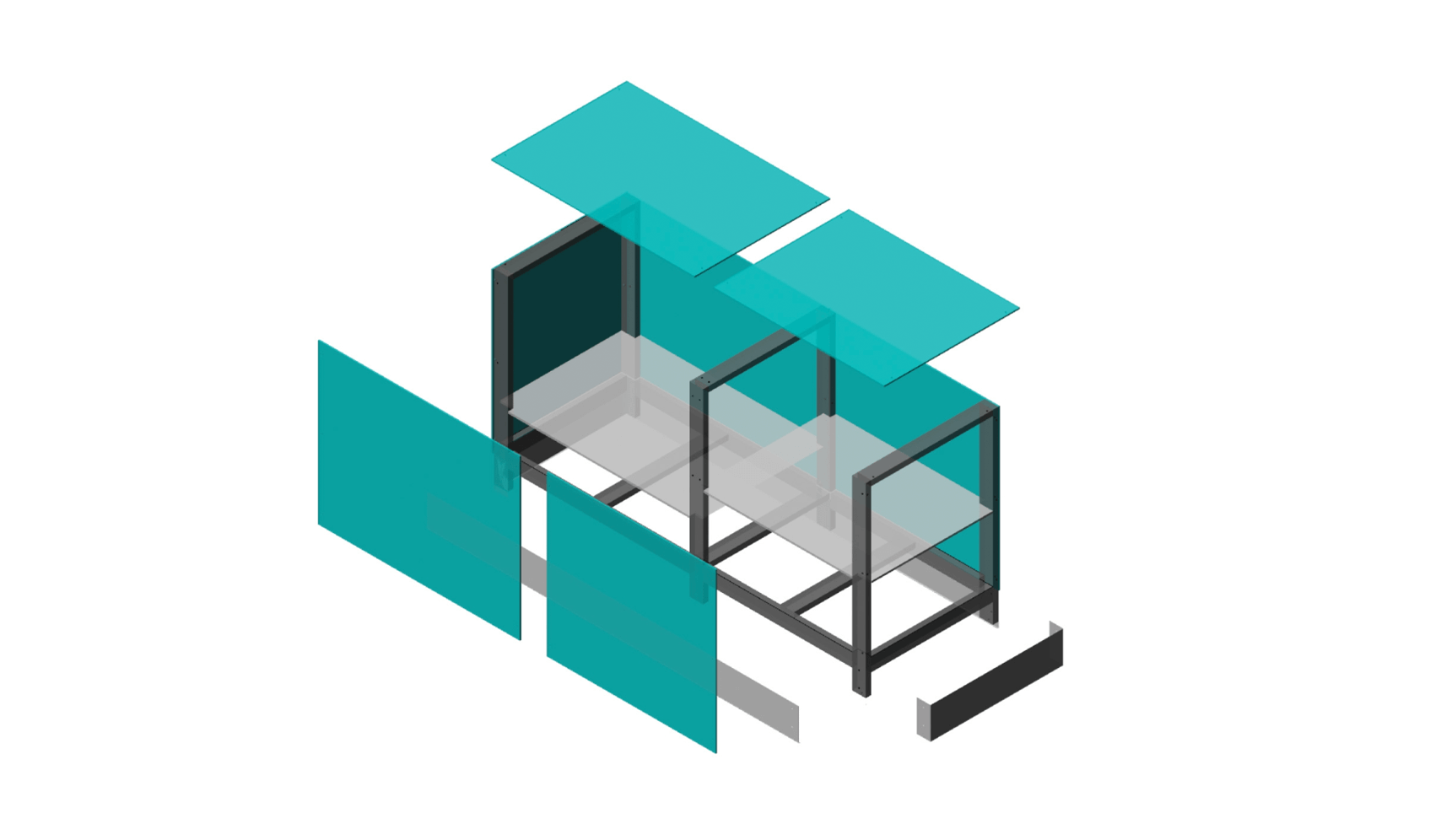

Mechanical assemblies.

Developing the Oracle Jet required precise coordination of complex mechanical assemblies. Subsystems were independently modelled and later integrated into a unified chassis architecture. Managing over 3000 parts necessitated the implementation of Teamcenter PLM software, streamlining supplier interactions and component releases.

Mechanical assemblies.

Developing the Oracle Jet required precise coordination of complex mechanical assemblies. Subsystems were independently modelled and later integrated into a unified chassis architecture. Managing over 3000 parts necessitated the implementation of Teamcenter PLM software, streamlining supplier interactions and component releases.

Mechanical assemblies.

Developing the Oracle Jet required precise coordination of complex mechanical assemblies. Subsystems were independently modelled and later integrated into a unified chassis architecture. Managing over 3000 parts necessitated the implementation of Teamcenter PLM software, streamlining supplier interactions and component releases.

Mechanical assemblies.

Complex assemblies were created to help develop the product architecture. Each subsystem was modelled independantly then we developed a common chassis to mount all the components.

With over 3000 parts in the machine we implemented Teamcenter a PLM software to help manage and release components to suppliers.

Mechanical assemblies.

Complex assemblies were created to help develop the product architecture. Each subsystem was modelled independantly then we developed a common chassis to mount all the components.

With over 3000 parts in the machine we implemented Teamcenter a PLM software to help manage and release components to suppliers.

Other projects.

Trailtech Battery12v Trail camera Battery

Cast Iron LidsIronclad Enamelware Lids

RECONTrolling motor

Air D1Luxury Loudspeaker

Hydration BottlePremium Reuseable Water Bottle

Retail CartPortable Retail Display Cart

Lowrance Eagle seriesFish Finder/chart plotter

Dock E30Studio Quality Compact Speaker

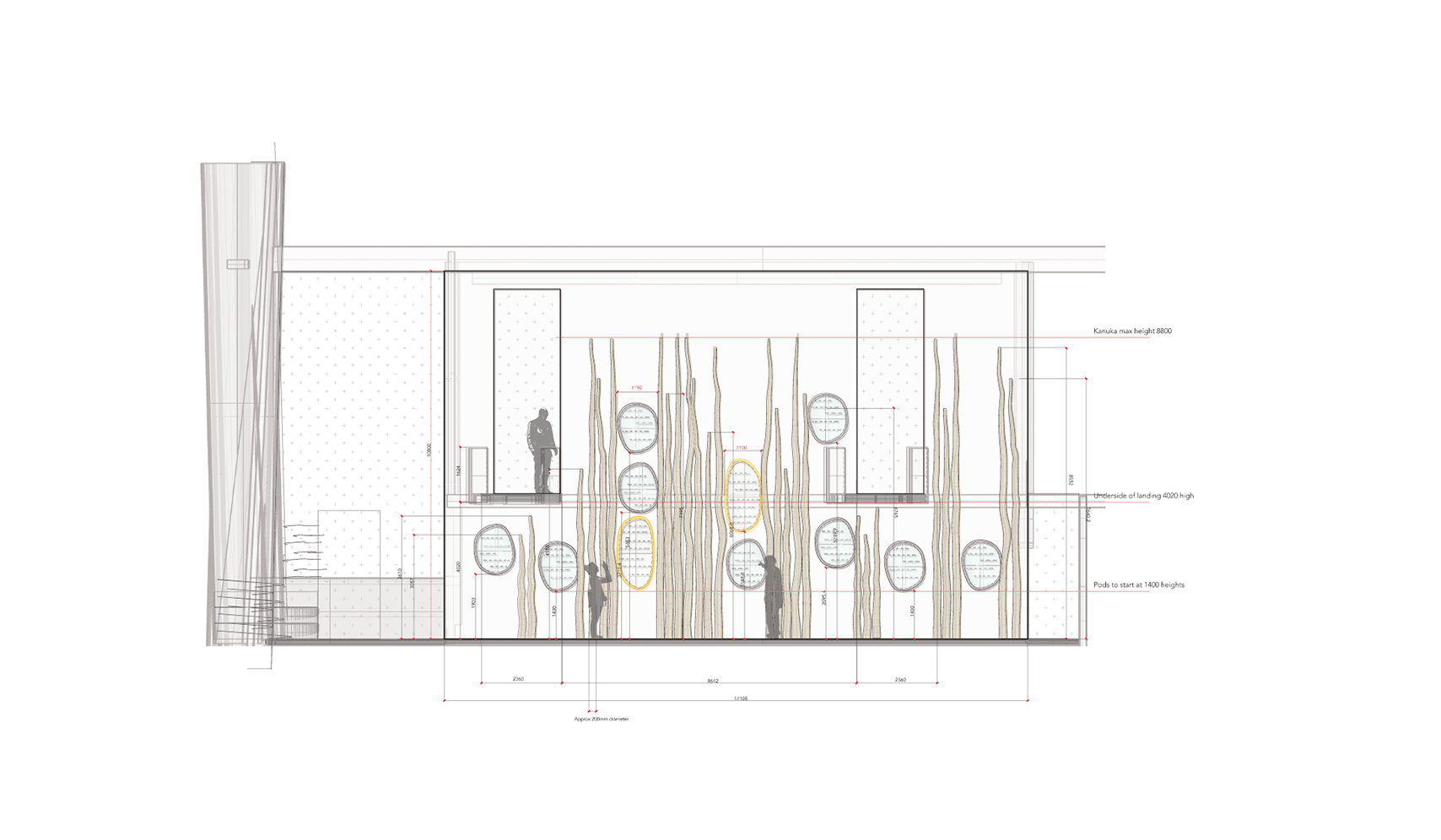

Resn labsSemi-permanent installation in Shenzhen China

HikoterraH4 Power System Visuals

NSX - UltrawideUltrawide marine display.

Jones JrMinimal multi-purpose task lamp

Ko Te Kihikihi Taku IngoaGovett Brewster Art Gallery

Ironclad BambooBamboo lids and Packaging

OrbitremoteA new frontier in remote audio control

Rotoiti BathMinimal aesthetic, compound curvature bathtub

BrevilleA selection of projects

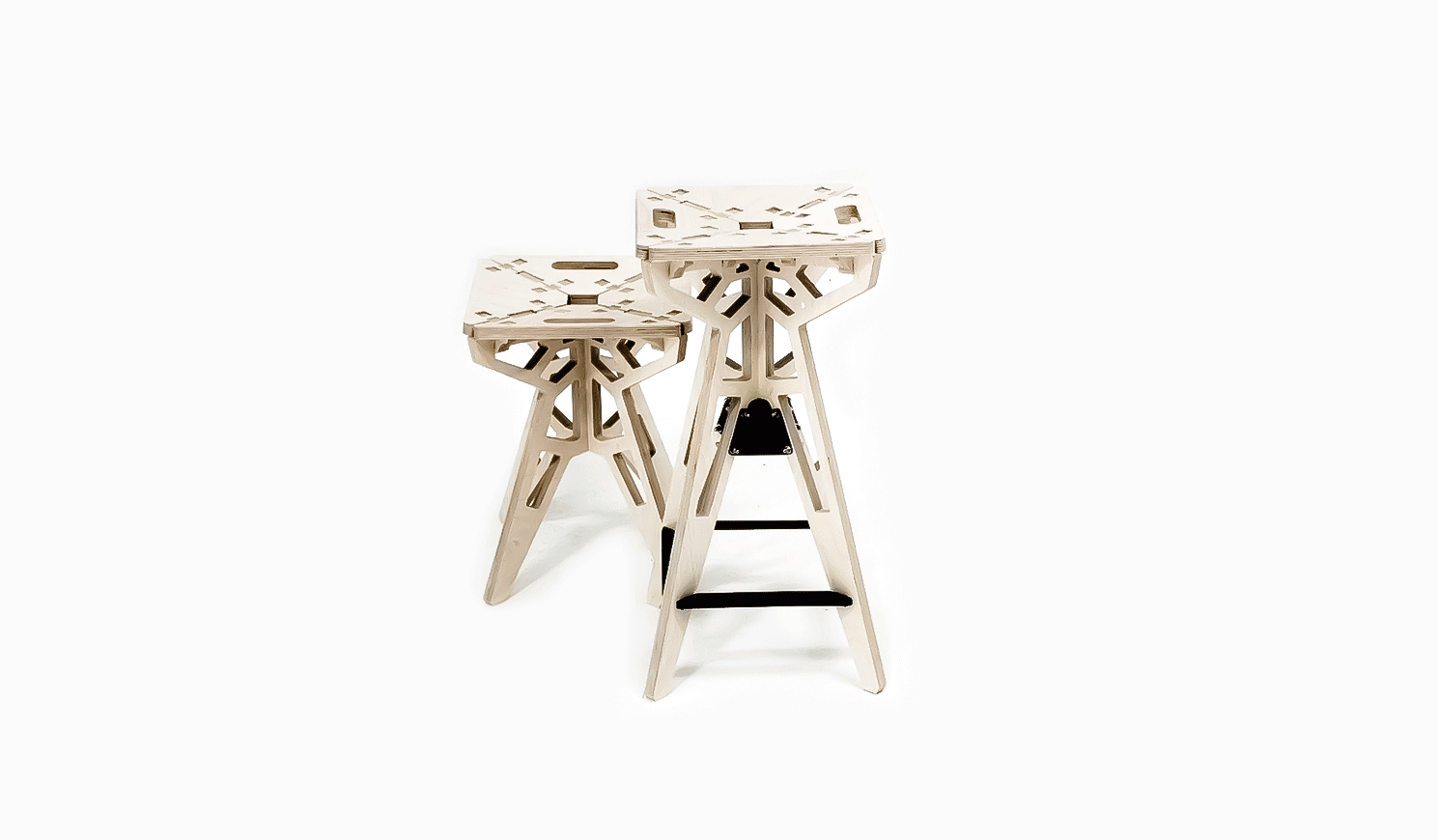

Space stoolsCNC cut stools

TVTRCompact soundbar

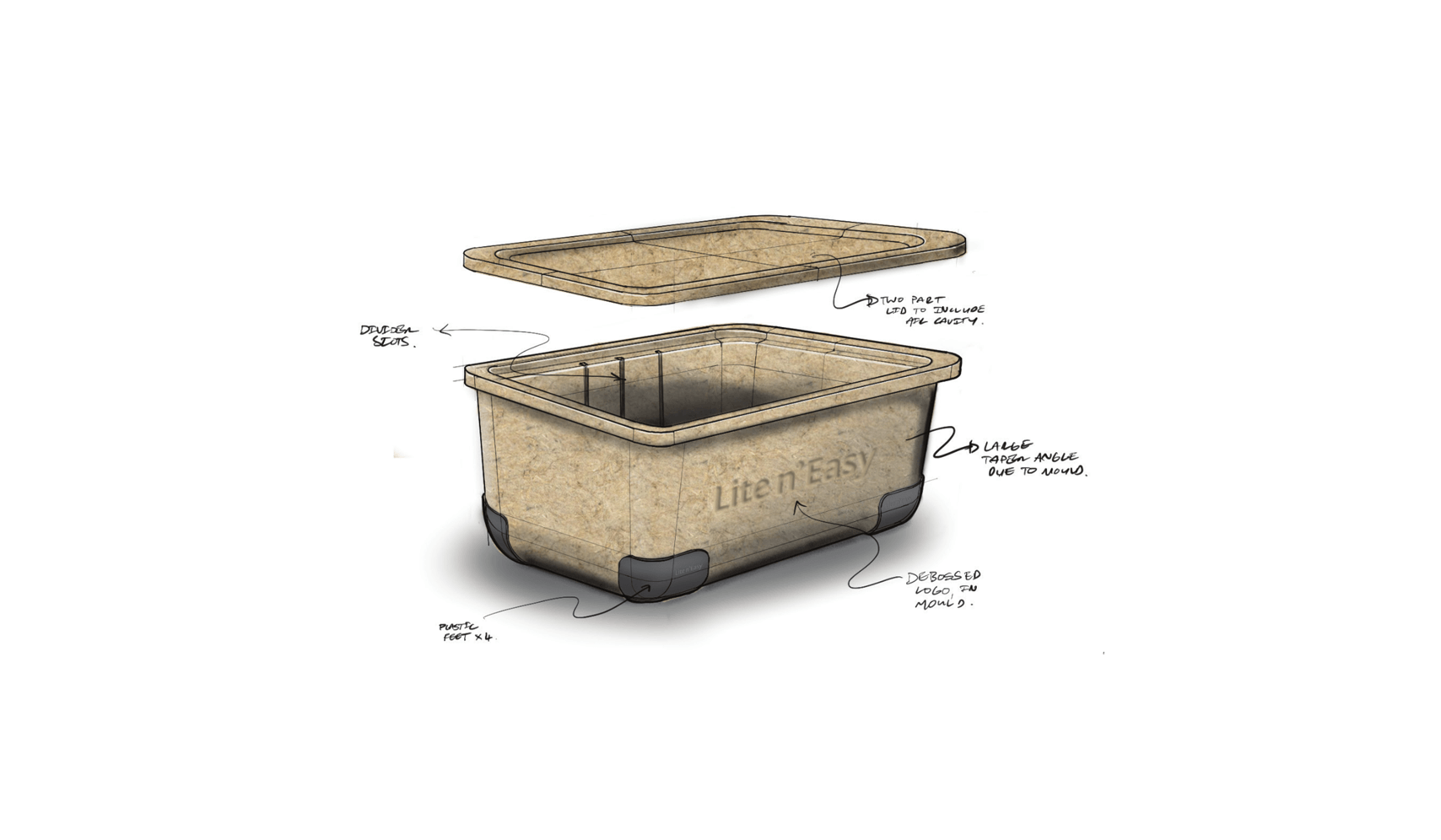

ThermoguardSustainable and re-useable food box

CEO SuiteChildrens desk and chair

Te MoungaCultural history exhibit

Gallipoli: The Scale of our WarExhibition furniture build

P70wAll in one soundbar

Meet the localsWellington zoo design and build

PK-01Portable kitchen

Maples kennelFlat pack dog kennel

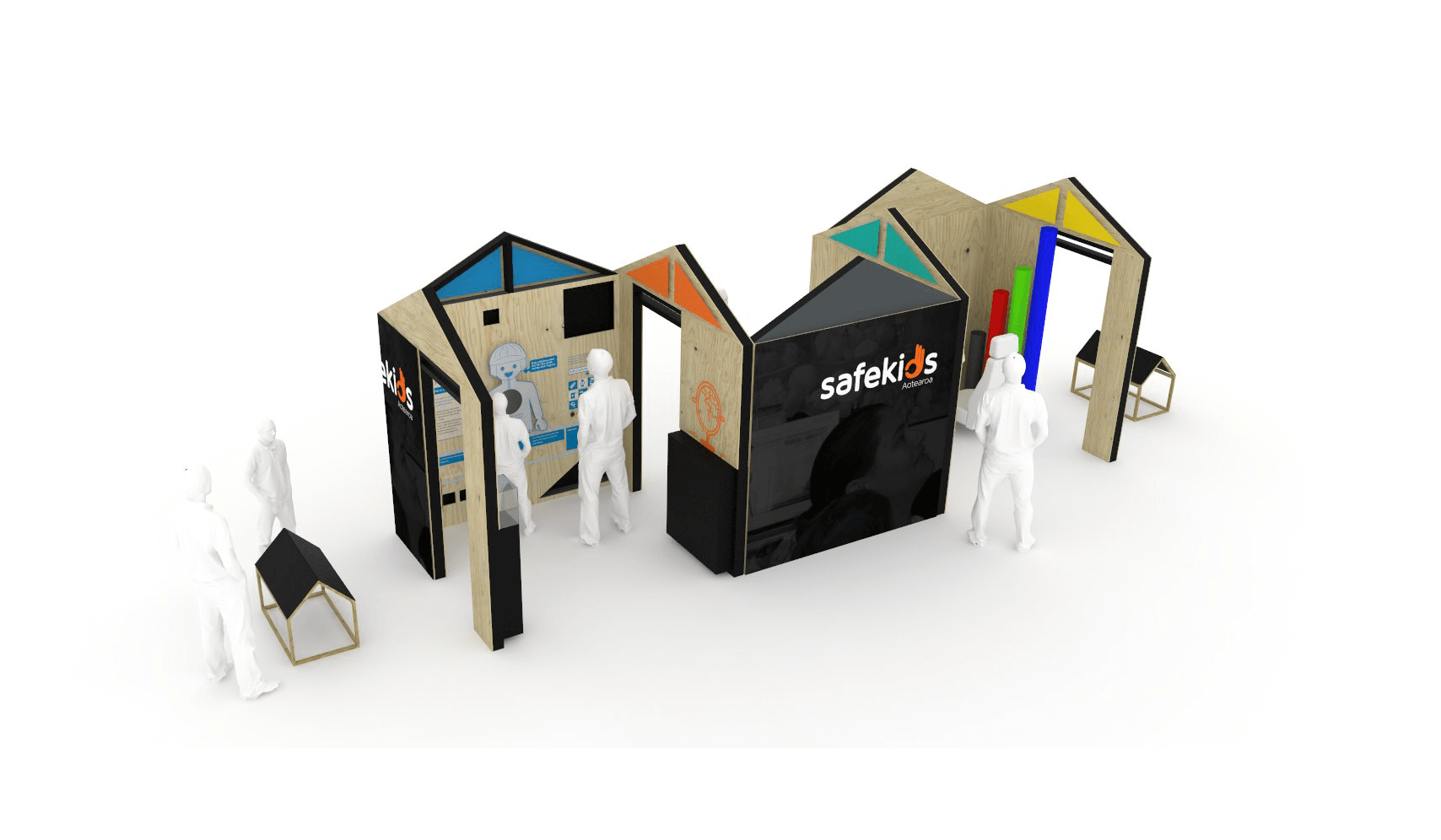

SafeKids AotearoaTouring popup exhibition

Barnaby Ward Design

5x Central Road, Kingsland

Auckland, 1021, NZ

© 2026

Book a Call

Book a Call Instagram.

Instagram. linkedin.

linkedin.